2026 Top Machine for Spinning Wool Innovations and Trends?

As we look ahead to 2026, the landscape of textile manufacturing is evolving rapidly. Innovations in technology shape the future of the machine for spinning wool. These machines are becoming faster, more efficient, and increasingly user-friendly.

Recent advancements focus on automation and sustainability. New machines integrate smart features. These systems analyze fiber quality in real-time. They help ensure consistent yarn production. However, challenges remain. Not all manufacturers can easily afford these innovations. Small businesses may struggle to keep pace.

Furthermore, the shift towards eco-friendly materials raises questions. Can new machines truly minimize waste? It's a critical reflection point. While technology offers exciting possibilities, the journey to sustainable spinning must continue. The machine for spinning wool requires ongoing dialogue and development to meet future demands.

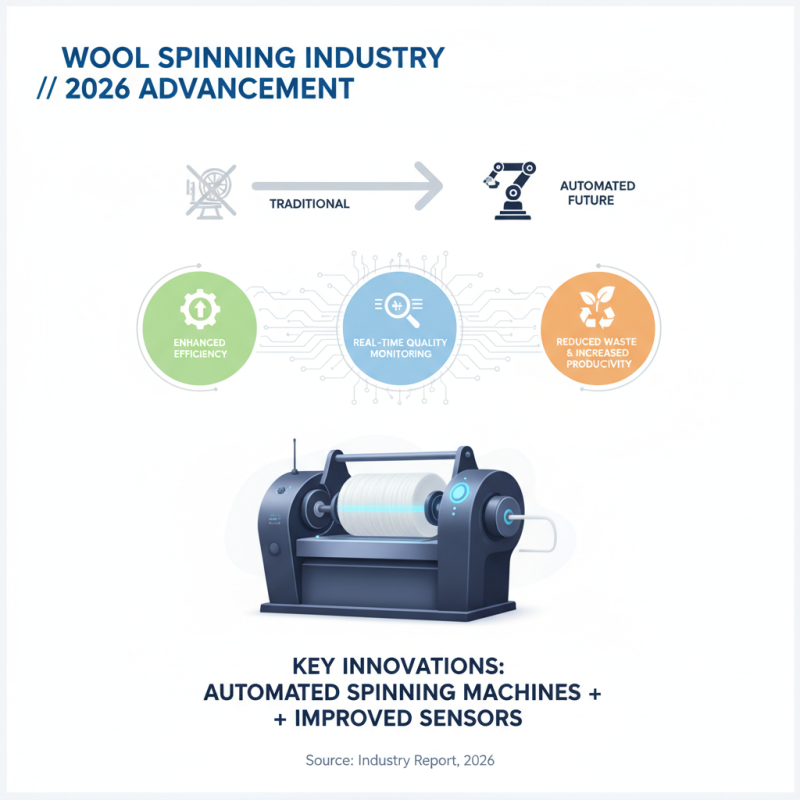

Emerging Technologies in Wool Spinning Machines for 2026

In 2026, the wool spinning industry is expected to witness significant advancements. Emerging technologies promise to enhance efficiency and quality. These innovations include automated spinning machines that reduce manual labor. With improved sensors, these machines can monitor wool quality in real-time. This reduces waste and increases productivity.

Sustainability is becoming a key focus as well. New systems integrate renewable energy sources to power machinery. This shift not only lowers costs but also minimizes environmental impact. Smaller-scale operations are exploring eco-friendly materials in their spinning processes. However, there’s a learning curve to implementing these technologies. Operators may face challenges in adapting to new systems.

The adoption of AI and machine learning is also on the rise. These technologies enable predictive maintenance, reducing downtime. However, the initial investment can be daunting for many businesses. Transitioning to smarter machines requires training and adjustments. It remains crucial for companies to evaluate their unique needs and capacities. Embracing innovation is essential, yet it must be approached with caution and responsibility.

Sustainability Trends Impacting Wool Spinning Innovations

Sustainability is reshaping the wool spinning industry dramatically. Reports indicate that around 70% of consumers now prefer sustainable materials. This trend is compelling manufacturers to rethink their processes. They are investing in eco-friendly raw materials. Sustainable practices are not merely optional but essential for market relevance.

Data from industry surveys show that over 60% of wool spinneries are adapting green technologies. This includes water-saving methods and energy-efficient machinery. However, challenges remain. Many spinneries lack the resources to fully transition to sustainable methods. The balance between innovation and cost is delicate. Some businesses face criticism for greenwashing their practices without significant change.

Another significant trend is the rise of recycled wool. About 30% of produced wool is now sourced from recycled fibers. This reduces waste and lowers the carbon footprint of the spinning process. Yet, the quality often raises concerns. Recycled wool can sometimes lack the durability of virgin fibers. Assessing these trade-offs is vital for the industry’s future. The path to sustainability is filled with reflections and necessary adjustments.

User-Centric Designs in Wool Spinning Equipment for Enhanced Efficiency

The wool spinning industry is evolving. User-centric designs are becoming essential. Machines now consider the experience of the spinner. This new focus improves efficiency and creativity in the spinning process. Features like adjustable tension and intuitive interfaces are gaining popularity. Spinners can customize their settings easily, making each project unique.

However, not all designs are perfect. Some machines may be too complex for beginners. The learning curve can be steep. This might discourage new spinners from embracing the craft. There is a push for simplicity in design. It’s vital that innovations cater not just to experts but to everyone.

Feedback from users can drive improvements. Manufacturers must listen closely to their customers. The goal is to create machines that serve all skill levels effectively. Making wool spinning accessible is key. Enhancing user experience is a journey, not a destination. Each step forward is an opportunity for growth.

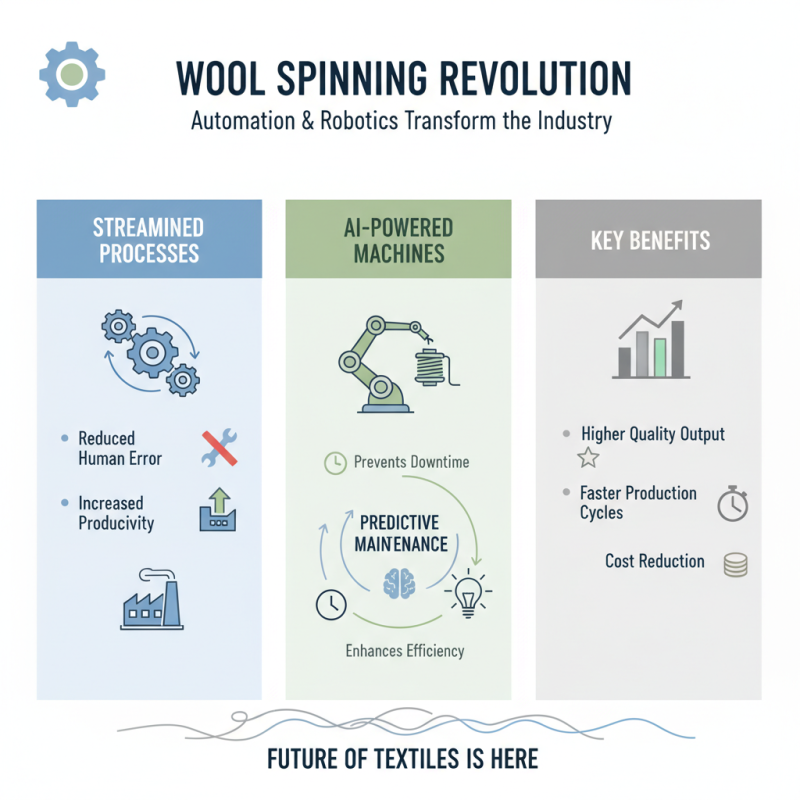

Integration of Automation and Robotics in Wool Spinning Processes

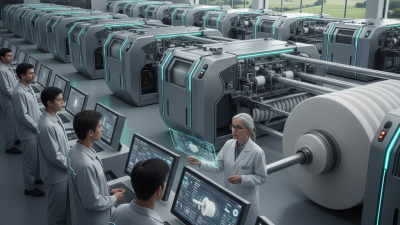

The wool spinning industry is witnessing a transformative wave of automation and robotics. Advanced technologies are streamlining processes, reducing human error, and increasing productivity. Machines equipped with artificial intelligence can predict maintenance needs, preventing downtime. This proactive approach enhances the efficiency of spinning operations.

Automation brings precision to every stage of wool processing. Robotic arms can handle large bales of wool, minimizing the physical strain on workers. However, the initial costs of integrating these technologies can be daunting for smaller enterprises. There’s a palpable tension between innovation and tradition. Not every facility is ready to embrace the change.

Some factories still rely on manual methods, valuing the artisanal touch. They fear losing craftsmanship in the pursuit of efficiency. Balancing automation with skilled labor is a challenge. Developers must consider how to incorporate human expertise into automated systems. Finding that equilibrium is essential for sustainable growth. The future remains uncertain, but it's clear that evolution is necessary.

Future Market Predictions for Wool Spinning Machinery Innovations

The wool spinning industry is on the verge of a transformative shift. As we look to 2026, advancements in machinery promise to revolutionize traditional processes. Digital technology and automation play crucial roles. Machine learning can optimize efficiency, predicting potential disruptions.

Tips: Embrace innovation. Stay informed about emerging technologies. Read industry reports regularly.

Sustainability remains a focal point. Manufacturers are rethinking materials. Eco-friendly practices are becoming essential. Machinery that reduces waste will thrive. However, the transition process can be challenging. Some facilities may struggle to upgrade equipment.

Tips: Assess current machinery. Identify areas for improvement. Prioritize upgrades that align with sustainable goals.

The market will witness a blend of traditional craftsmanship and modern technology. Skilled labor will still be important. Balancing automation with manual skills is key. Unexpected hurdles may arise during this integration. Monitoring progress is crucial for success.

2026 Top Innovations in Wool Spinning Machinery

Related Posts

-

What is a Machine for Spinning Wool and How Does It Work?

-

What is a Wool Spinning Machine and How Does it Work?

-

Top 10 Wool Spinning Machines You Need to Know for Your Crafting Projects

-

How to Choose the Best Machine for Spinning Wool Based on Expert Data and User Reviews

-

Why You Should Choose an Automatic Wool Spinning Machine for Your Business

-

2026 How to Choose the Best Automatic Wool Spinning Machine for Your Needs