Why You Should Choose an Automatic Wool Spinning Machine for Your Business

In the rapidly evolving world of textile manufacturing, the choice of machinery can significantly impact the quality and efficiency of production processes. According to Dr. Emily Carter, a renowned expert in textile engineering, “Investing in an automatic wool spinning machine not only enhances productivity but also ensures superior yarn quality.” As businesses strive to optimize their operations, the integration of advanced technologies like automatic wool spinning machines becomes paramount.

These state-of-the-art machines are designed to streamline wool processing, providing consistent results that manual methods often fail to achieve. By leveraging automation, manufacturers can significantly reduce labor costs while improving the overall output. Furthermore, the precision of an automatic wool spinning machine allows for the production of finer and more durable yarns, meeting the increasing demand for high-quality textile products in the global market.

Embracing automation in wool spinning not only aligns with industry trends towards sustainability and efficiency but also positions businesses for future growth. With the insights from experts like Dr. Carter, it becomes clear that the decision to invest in an automatic wool spinning machine is a strategic move for companies aiming to thrive in a competitive environment.

Benefits of Using Automatic Wool Spinning Machines in Modern Textile Production

Automatic wool spinning machines have revolutionized modern textile production, offering numerous benefits that enhance efficiency and product quality. One of the primary advantages is increased productivity. These machines can operate continuously with minimal human intervention, significantly reducing labor costs and time associated with manual spinning. By automating the spinning process, businesses can scale up their operations and meet higher demand without compromising on quality.

In addition to productivity, automatic wool spinning machines ensure consistency in yarn production. The precision of automated systems leads to uniformity in yarn thickness, strength, and texture, which is crucial for maintaining high-quality standards in textile products. Furthermore, the technology employed in these machines often includes advanced monitoring systems that can detect anomalies in the spinning process in real time, allowing for prompt adjustments and minimizing waste. This not only optimizes the use of resources but also contributes to sustainable practices in the textile industry.

Benefits of Using Automatic Wool Spinning Machines in Modern Textile Production

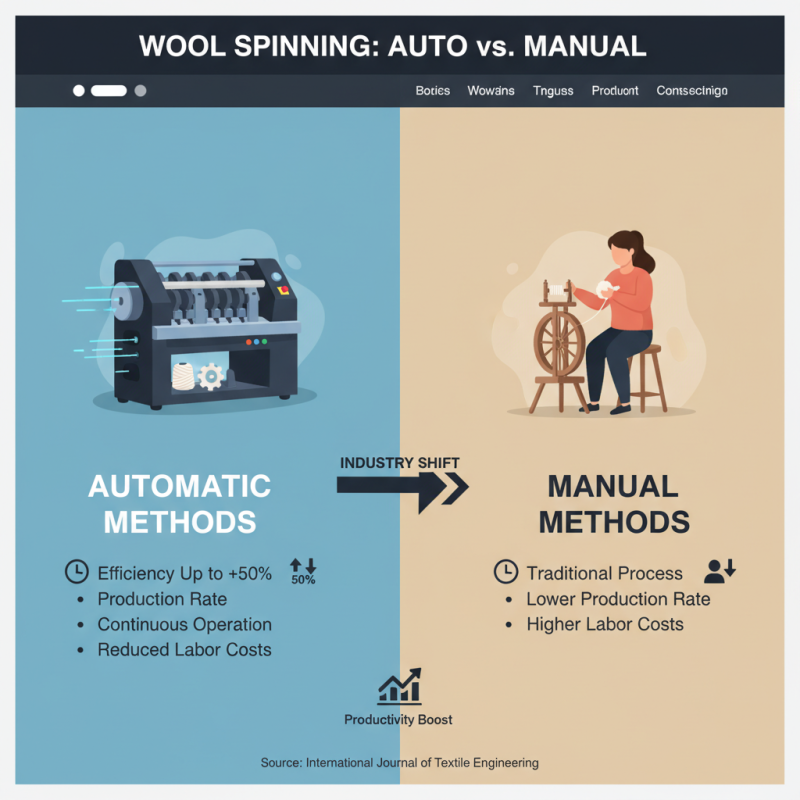

Comparative Analysis: Automatic vs. Manual Wool Spinning Techniques

When evaluating wool spinning techniques, the choice between automatic and manual methods is pivotal for businesses aiming to enhance efficiency and productivity. Recent industry reports indicate that automatic wool spinning machines can increase production rates by up to 50% compared to traditional manual methods. This significant advancement is largely attributed to the ability of machines to operate continuously, reducing downtime and maximizing output. For instance, a study published in the International Journal of Textile Engineering noted that automated processes not only streamline yarn production but also minimize labor costs associated with manual spinning techniques.

Moreover, consistency in quality is another critical factor favoring automatic wool spinning machines. According to a report by the Textile Research Institute, automated spinning systems yield yarns that have lower variability in diameter and tensile strength than those produced manually. This enhanced quality control is essential for manufacturers looking to meet the rigorous standards of the textile market. Additionally, automatic machines often incorporate advanced technology such as digital monitoring systems, allowing for real-time adjustments that enhance both product uniformity and overall operational efficiency. With the textile industry increasingly focused on sustainability and productivity, the advantages of automatic wool spinning techniques become more compelling.

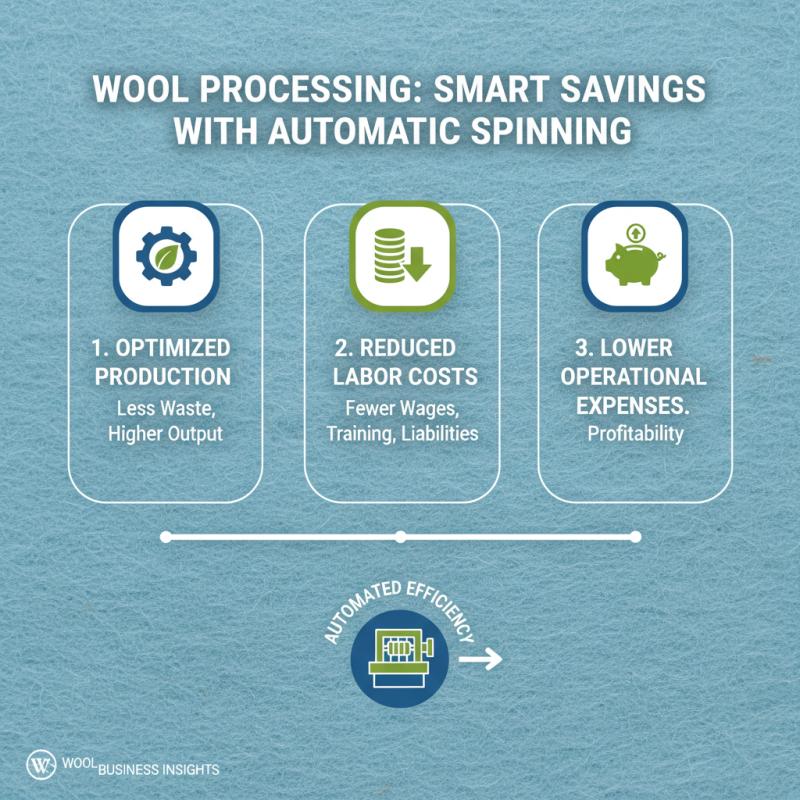

Cost Efficiency: How Automatic Spinning Machines Reduce Operational Expenses

When considering the financial implications of running a wool processing business, investing in an automatic wool spinning machine can yield significant cost efficiencies. These machines are designed to optimize production rates while minimizing waste, which in turn lowers the overall operational expenses. By automating the spinning process, businesses can reduce the labor force required, thereby cutting down on wages, training costs, and potential employee-related liabilities.

Moreover, automatic spinning machines typically operate with higher precision and consistent quality than manual processes. This capability not only enhances the end product but also minimizes the need for rework and waste, translating into further savings. With reduced downtime and maintenance needs, businesses can run their operations more smoothly, ensuring that production schedules are maintained without the interruptions that often come with manual spinning practices. In the long run, the investment in automatic technology can lead to a more streamlined and financially viable operation in the competitive wool industry.

Enhancing Productivity: The Role of Automation in Wool Spinning Processes

The integration of automation in wool spinning processes significantly enhances productivity and operational efficiency. By adopting an automatic wool spinning machine, businesses can streamline their production cycles, reducing the time spent on manual tasks. This leads to improved consistency in product quality, as machines can maintain precision and uniformity far better than human hands. Automation allows for quicker turns in production, meaning businesses can respond more swiftly to market demands without compromising quality.

Moreover, automated systems minimize labor costs and reduce the risk of errors commonly associated with manual labor. This enables staff to focus on more strategic roles within the business, such as quality control and innovation in product design. As a result, companies can not only produce more wool but also explore new product lines and market opportunities, thus expanding their reach. By leveraging advanced technology in wool spinning, businesses position themselves to thrive in a competitive landscape while maximizing resource utilization and efficiency.

Quality Control: Ensuring Consistent Yarn Quality with Automatic Machines

The use of automatic wool spinning machines significantly enhances quality control in yarn production. These machines are designed to maintain uniformity in the spinning process, minimizing human error that can often lead to inconsistencies in yarn quality. By automating the spinning process, manufacturers can ensure that the yarn produced adheres to precise specifications, reducing the variation in fiber thickness and twist. This consistency is vital for creating high-quality finished products that meet customer expectations.

Additionally, automatic machines are equipped with advanced monitoring systems that provide real-time data on the spinning process. This allows for immediate adjustments to be made if any deviations from the desired quality are detected. The integration of technology not only improves efficiency but also ensures that each batch of yarn meets stringent quality standards. Producers can track performance metrics, enabling them to refine their processes over time and maintain a steady output of premium yarn. Thus, opting for an automatic wool spinning machine is a strategic choice for businesses aiming to deliver high-quality yarn consistently.

Related Posts

-

Top 10 Benefits of Eri Silk Spinning Machines for Sustainable Production

-

Why You Should Invest in an FDY Yarn Machine for Your Textile Business Growth

-

How to Choose the Best Machine for Spinning Wool Based on Expert Data and User Reviews

-

How to Choose the Best Yarn Spinning Equipment for Your Needs

-

Why Choose a Yarn Spinner Machine for Efficient Textile Production Solutions

-

Top 10 Spinning Machines for Yarn: An Ultimate Guide for Efficient Production