Top 10 Best FDY Yarn Machines for High Quality Fabric Production

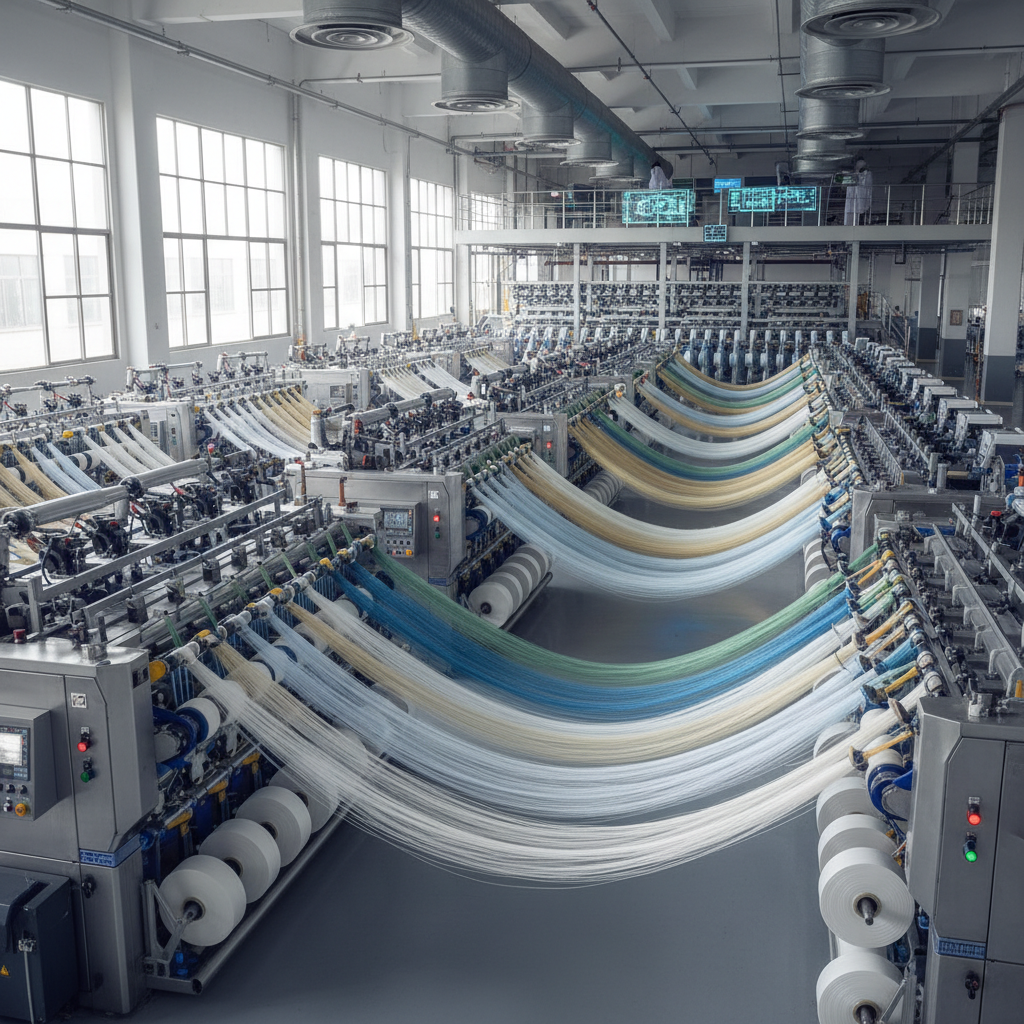

The textile industry is witnessing a transformative shift towards high-quality fabric production, largely driven by advancements in technology and machinery. Among these innovations, the FDY yarn machine stands out as a pivotal component in enhancing fabric quality and efficiency. According to a recent market report from Textile World, the demand for FDY yarn has grown by over 25% in the past year, underscoring its critical role in meeting the evolving needs of both manufacturers and consumers.

Expert in textile machinery, Dr. Emily Chen, notes, "The FDY yarn machine is not just a processing tool; it represents the future of high-performance textiles." This statement encapsulates the essence of how the right machinery can significantly influence the quality of fabric production. As manufacturers seek to produce finer, more durable fabrics, investing in state-of-the-art FDY yarn machines becomes essential. This article delves into the top 10 FDY yarn machines that are setting new standards in the industry, ensuring that producers can deliver exceptional fabrics that meet market demands.

Benefits of Using FDY Yarn Machines for High-Quality Fabric Production

FDY (Fully Drawn Yarn) machines play a crucial role in the production of high-quality fabrics, offering numerous benefits that enhance the overall manufacturing process. One of the primary advantages is the machine's ability to produce yarns with consistent diameter and improved tensile strength. According to a report by Technavio, the global FDY yarn market is projected to grow by over $1 billion from 2021 to 2025, showcasing the increasing demand for reliable and high-performance yarns in the textile industry. This growth is largely attributed to the enhanced quality and durability of fabrics produced using advanced FDY machines, making them a preferred choice for manufacturers aiming for superior output.

Moreover, FDY yarn machines contribute to greater efficiency in fabric production. By utilizing continuous filament technology, these machines reduce the number of defects in the yarn, ultimately minimizing waste and lowering operational costs. A study published in the International Journal of Clothing Science and Technology highlighted that manufacturers using FDY machines reported a 15% reduction in production time and a 20% decrease in material usage compared to conventional spinning methods. This efficiency not only boosts productivity but also promotes sustainability within the textile industry, making FDY machines an essential investment for modern fabric producers.

Key Features to Look for in Top-Notch FDY Yarn Machines

When selecting the best FDY (Fully Drawn Yarn) machines for high-quality fabric production, it’s crucial to consider several key features that drive efficiency and output. One of these features is the machine’s speed and production capacity. According to a report by the International Textile Manufacturers Federation (ITMF), advanced FDY machines can produce up to 2000 meters of yarn per minute, significantly enhancing productivity in a competitive market. A higher throughput not only accelerates production cycles but also optimizes labor costs and energy consumption.

Another essential feature to look for is the precision in yarn tension control and temperature management. A study from Textile Research Journal highlights that machines equipped with state-of-the-art tension sensors can maintain consistent yarn quality with minimal breaks. This precision is vital, as even slight variations can lead to defects in the final fabric. Additionally, effective heat management is critical in ensuring that the yarn retains its strength and elasticity, which are essential qualities for durable textile applications. Therefore, understanding these technical aspects can notably influence a manufacturer's choice in investing in FDY yarn machines tailored to their production needs.

Top 10 Best FDY Yarn Machines for High Quality Fabric Production

| Machine Model | Max Fiber Count (Denier) | Production Speed (m/min) | Power Consumption (kW) | Weight (kg) | Key Features |

|---|---|---|---|---|---|

| Model A | 1000D | 300 | 15 | 2000 | High speed operation, low vibration |

| Model B | 1200D | 400 | 18 | 2500 | Automated yarn tension control |

| Model C | 800D | 250 | 12 | 1800 | Energy-efficient, compact design |

| Model D | 1500D | 500 | 20 | 3000 | High efficiency, user-friendly interface |

| Model E | 600D | 220 | 10 | 1500 | Versatile, easy maintenance |

| Model F | 900D | 350 | 16 | 2400 | Advanced monitoring features |

| Model G | 1100D | 450 | 19 | 2800 | User-friendly software, fast setup |

| Model H | 1300D | 480 | 22 | 3200 | Sturdy and durable design |

| Model I | 700D | 260 | 14 | 1700 | Easy operation, low maintenance cost |

| Model J | 400D | 200 | 8 | 1200 | Compact with advanced features |

Industry Trends: The Growing Demand for FDY Yarn in Fabric Manufacturing

The growing demand for Fully Drawn Yarn (FDY) in fabric manufacturing is reflective of significant market trends. The market for polyester FDY is projected to reach a staggering $38.2864 billion in 2024, with an expected increase to $40.0930 billion in 2025, and a remarkable growth to $56.8973 billion by 2033. This upward trajectory illustrates the escalating necessity for high-quality yarns in various textile applications, underscoring the shift towards superior fabric characteristics driven by consumer preferences and technological advancements.

Additionally, the nylon 6 filament yarn market is also experiencing notable expansion, with an anticipated market size of $18.43 billion in 2023, expected to rise to $27.94 billion by 2032, yielding a compound annual growth rate (CAGR) of 4.4%. The polyester filament yarn market is projected to reach $80.951 billion by 2025, with estimates suggesting it could soar to $172.12 billion by 2034, achieving a CAGR of approximately 8.74% from 2025 to 2034. These figures highlight the robust growth potential across various segments of the fabric production industry, driven by the increasing demand for high-quality materials and innovative manufacturing processes.

Technical Specifications: Comparing the Leading FDY Yarn Machines on the Market

When evaluating the leading FDY yarn machines available on the market, technical specifications play a crucial role in determining their capability for high-quality fabric production. Machines vary significantly in terms of filament count, speed output, and energy efficiency. For instance, some high-end models boast a filament count of up to 1440, which allows for finer yarn production, while maintaining high operational speeds of over 1500 meters per minute. This balance between speed and quality ensures that manufacturers can meet the growing demand for lightweight and durable fabrics.

In addition to filament count and speed, modern FDY yarn machines are equipped with advanced features such as real-time monitoring systems and automated adjustments. These innovations enhance the consistency of yarn quality and reduce the likelihood of defects during production. Furthermore, energy-efficient designs are becoming increasingly important, with some machines utilizing up to 30% less energy compared to their predecessors. By comparing these technical specifications, manufacturers can select the ideal FDY yarn machine that not only fits their production needs but also contributes to sustainable manufacturing practices.

Investment Considerations: Cost vs. Quality in FDY Yarn Machinery Choices

When considering the investment in FDY (Fully Drawn Yarn) yarn machines, the critical balance between cost and quality must be assessed rigorously. Recent industry reports indicate that the global demand for FDY is projected to reach approximately 2.4 million tons by 2025, driven largely by the booming textile industry. This surge emphasizes the importance of selecting machinery that not only meets production needs but also ensures high-quality output. Investing in high-quality FDY machines can lead to lower maintenance costs and improved efficiency over time, potentially offsetting the initial higher expenditure.

Additionally, the variance in machine costs can be considerable, often ranging from $50,000 to $300,000 depending on features and capabilities. A comprehensive analysis by Textile Machinery Review suggests that spending more upfront on state-of-the-art technology can yield up to a 20% increase in productivity and a 15% reduction in raw material waste. This data illustrates that while the initial investment might be daunting, the long-term savings and quality enhancements make it a prudent decision for textile manufacturers aiming for competitive advantage in the high-quality fabric market.

Related Posts

-

Why You Should Invest in an FDY Yarn Machine for Your Textile Business Growth

-

Unlocking the Art of Weaving: How Spinning Wool into Yarn Machines Transform Craftsmanship

-

How to Choose the Best Machine for Spinning Wool Based on Expert Data and User Reviews

-

10 Best Spinning Machines for Yarns to Increase Production Efficiency by 30 Percent

-

2025 Top 10 Yarn Manufacturing Machines: Boost Efficiency with Advanced Technology

-

Top 10 Spinning Machines for Yarn: An Ultimate Guide for Efficient Production