Top 10 Best PP Multifilament Yarn Machines for Efficient Production

In the ever-evolving textile industry, efficiency and quality are paramount, particularly in the production of synthetic fibers. One of the most critical components in this process is the pp multifilament yarn machine, which plays a vital role in the creation of high-performance yarns used in a variety of applications. These machines not only ensure uniformity and strength in the yarn produced but also enhance the overall productivity of textile manufacturing processes. As demand for lightweight and durable materials continues to grow, the innovation behind pp multifilament yarn machines becomes increasingly important.

This report delves into the top 10 best pp multifilament yarn machines available in the market today, highlighting their features and efficiency. By examining these advanced machines, manufacturers can make informed decisions that align with their production goals. From energy efficiency to production speeds, the right equipment can significantly impact operational success and cost-effectiveness. In an industry where precision and reliability are essential, understanding the capabilities of these machines is crucial for companies looking to maintain a competitive edge.

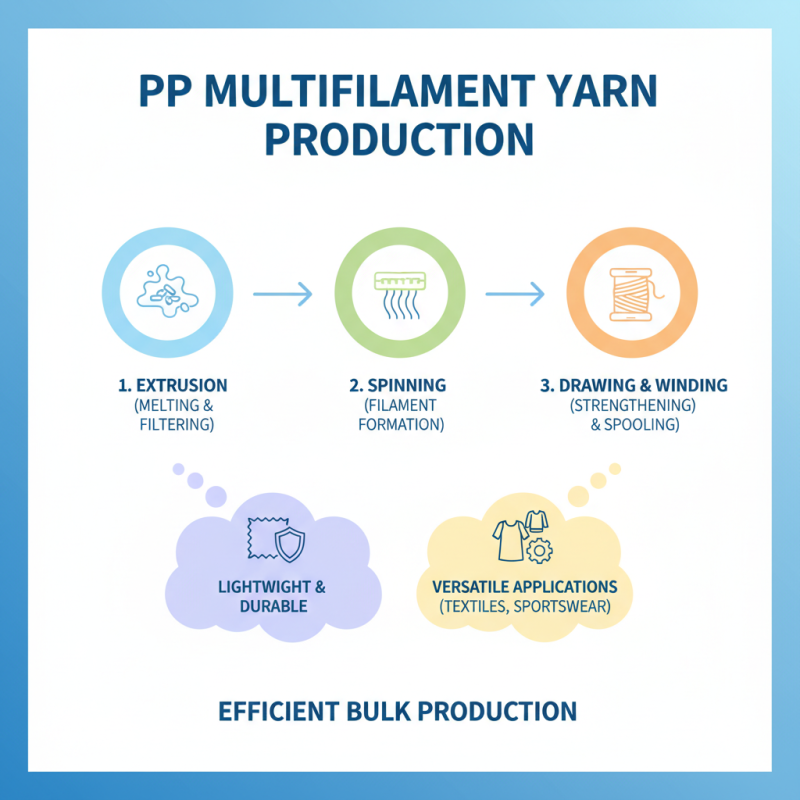

Overview of PP Multifilament Yarn Production

PP multifilament yarn production has gained considerable attention in the textile industry due to its lightweight, durable, and versatile nature. The process involves extruding polypropylene, a thermoplastic polymer, into thin filaments that can be woven into various fabric types. This method not only enhances the mechanical properties of the yarn but also allows for efficient bulk production, catering to the demands of different applications ranging from industrial textiles to sportswear.

When producing PP multifilament yarn, choosing the right machinery is crucial for optimizing efficiency and quality. Modern yarn machines are equipped with advanced features such as controlled temperature settings, precise extrusion rates, and automated winding systems. These innovations contribute to reducing waste and ensuring uniformity in the final product.

**Tips:** To maximize production efficiency, it is essential to regularly maintain and calibrate your machinery. Additionally, monitoring the quality of the raw materials used will significantly affect the final yarn product. Implementing a quality control system can help detect inconsistencies early in the production process, leading to better overall performance and reduced downtime. Furthermore, consider experimenting with different twisting techniques as these can enhance the final yarn’s strength and texture.

Key Features of High-Performance Yarn Machines

When selecting high-performance PP multifilament yarn machines, several key features significantly impact production efficiency and quality. One of the most vital characteristics is the machine’s speed and versatility. Industry reports suggest that modern yarn machines can operate at speeds of up to 3000 meters per minute, enhancing throughput while maintaining consistent quality. This high speed is crucial for manufacturers aiming to meet increased demand without compromising on the strength or texture of the yarn produced.

Another important feature is the automation level of the machine. Advanced yarn machines employ automated threading and tension control systems, which not only reduce manual labor but also minimize the risk of errors during production. According to a recent market analysis, manufacturers that implement high levels of automation in their production lines have reported efficiency improvements of 20-30%. Furthermore, the integration of smart technologies, such as IoT and real-time monitoring systems, allows for predictive maintenance, reducing downtime and operational costs significantly.

Lastly, material compatibility and production flexibility are critical to high-performance yarn machines. The ability to easily switch between different types of fibers and yarn configurations not only caters to diverse market needs but also allows manufacturers to optimize their production processes. Reports indicate that facilities capable of producing a wider variety of yarn types witness a 40% increase in market share when compared to those restricted to single-product lines. These key features contribute immensely to ensuring that yarn production is not only efficient but also adaptable to ever-evolving consumer demands.

Top 10 PP Multifilament Yarn Machines Evaluated

The production of polypropylene (PP) multifilament yarn has gained traction in various industries, including textiles and fishing nets, due to its excellent strength-to-weight ratio and durability. According to recent industry analysis, the global market for multifilament yarn is projected to reach a significant milestone, with a CAGR of around 6.5% from 2021 to 2026. This growth is fueled by increasing demand in the automotive and home decor sectors, which showcase the versatility of PP multifilament yarn.

The evaluation of PP multifilament yarn machines is critical for manufactures seeking to enhance productivity and reduce waste. A comprehensive report by the Textile Machinery Industry Association highlights that advanced machines equipped with smart technology can improve production efficiency by over 20%, while also lowering energy consumption. Furthermore, these machines are designed to facilitate smoother yarn production, resulting in fewer defects and enhanced fiber integrity, which are essential for meeting the stringent quality standards of end products. As companies continue to invest in state-of-the-art machinery, the importance of selecting the right equipment becomes evident for sustaining competitive advantage in this evolving market.

Top 10 Best PP Multifilament Yarn Machines for Efficient Production

| Rank | Model | Production Capacity (kg/h) | Power Consumption (kW) | Weight (kg) | Price Range ($) |

|---|---|---|---|---|---|

| 1 | Model A | 200 | 150 | 800 | 20000 - 25000 |

| 2 | Model B | 180 | 120 | 750 | 18000 - 23000 |

| 3 | Model C | 150 | 100 | 700 | 15000 - 20000 |

| 4 | Model D | 220 | 160 | 850 | 22000 - 27000 |

| 5 | Model E | 200 | 140 | 800 | 20000 - 25000 |

| 6 | Model F | 190 | 130 | 780 | 17000 - 22000 |

| 7 | Model G | 210 | 155 | 900 | 21000 - 26000 |

| 8 | Model H | 175 | 115 | 740 | 16000 - 21000 |

| 9 | Model I | 160 | 125 | 760 | 15000 - 20000 |

| 10 | Model J | 170 | 135 | 770 | 16000 - 21000 |

Comparative Analysis of Machine Efficiency and Output

When evaluating machines for producing PP multifilament yarn, a comprehensive comparative analysis of efficiency and output is essential. The efficiency of machinery in this context is often determined by several factors, including the speed of operation, energy consumption, and ease of maintenance. Machines that are engineered with advanced technology, such as automated controls and optimized tension systems, tend to enhance production rates while minimizing downtime. Additionally, user-friendly interfaces and smart monitoring systems can significantly contribute to operational efficiency, allowing operators to adjust settings with precision for different yarn specifications.

Output levels also play a critical role in assessing the best machinery for yarn production. High-output machines are designed to produce a greater volume of yarn per hour without compromising on quality. This capability hinges on the machine’s design, including the configuration of extruders and spindles, as well as the overall build quality. A well-designed machine will ensure consistent filament thickness and strength, resulting in a more reliable final product. By comparing these performance metrics across various models, manufacturers can identify the machines that best meet their production goals, fostering an environment of efficiency and cost-effectiveness in the yarn manufacturing process.

Top 10 Best PP Multifilament Yarn Machines - Efficiency and Output Comparison

Future Trends in PP Multifilament Yarn Manufacturing Technology

The PP multifilament yarn manufacturing industry is poised for significant advancements as technology continues to evolve. One of the most promising trends is the integration of automation and smart manufacturing practices. According to a recent report by the Textile Machinery Association, automation can enhance production efficiency by up to 30% while minimizing human error. This shift not only accelerates production times but also lowers operational costs, making it a crucial focus for manufacturers aiming to stay competitive in a rapidly changing marketplace.

Moreover, the advent of eco-friendly processes is becoming increasingly vital in yarn production. With more consumers demanding sustainable products, manufacturers are exploring bio-based PP materials and recycling methods to reduce their carbon footprint. A study by the International Fiber Association estimates that implementing sustainable practices can increase market share by 20%, indicating a clear financial incentive for factories to adopt greener technologies.

Tips: When considering investments in manufacturing technology, prioritize systems that allow for easy upgrades and maintenance. This flexibility can enable your facility to quickly adapt to future developments in yarn technology, ensuring long-term viability. Additionally, invest in employee training to efficiently handle new machines and technology, as skilled personnel are key in optimizing production processes.

Related Posts

-

Top 10 Tips for Choosing the Right PP Multifilament Yarn Machine

-

Top Yarn Manufacturing Machines for Efficient Production in 2023

-

How to Choose the Best FDY Yarn Machine for Optimal Production Efficiency

-

What is Open End Spinning? Understanding Its Benefits and Applications in Textile Industry

-

Why You Should Choose a Home Wool Spinning Machine for Your Crafting Needs

-

How to Choose the Best Automatic Yarn Spinning Machine for Your Business