How to Choose the Best Automatic Yarn Spinning Machine for Your Business

In the rapidly evolving textile industry, the choice of equipment can significantly impact production efficiency and product quality. As businesses seek to enhance their manufacturing processes, selecting the right automatic yarn spinning machine becomes crucial. Renowned industry expert Dr. Emily Carter, a leading authority in textile technology, emphasizes, "Investing in the right automatic yarn spinning machine not only boosts productivity but also enhances the overall quality of the final yarn product."

With a plethora of options available in the market, understanding the key features and specifications of various models is essential for making an informed decision. The automatic yarn spinning machine can vary significantly in terms of technology, output capacity, and operational efficiency. As companies strive to meet increasing consumer demands for quality and sustainability, having the right machine can set them apart from competitors and support long-term business growth.

Therefore, it is imperative for business owners and textile manufacturers to thoroughly assess their unique needs and the technical capabilities of different automatic yarn spinning machines. This careful evaluation will ensure they select the best equipment that aligns with their operational goals and production demands, ultimately leading to enhanced performance and market competitiveness.

Understanding Your Yarn Production Needs

When selecting the best automatic yarn spinning machine for your business, it is essential to start by thoroughly understanding your yarn production needs. Assess the type of yarn you plan to produce, whether it’s cotton, wool, or synthetic fibers, as different machines cater to different materials. Additionally, consider the desired yarn thickness and texture, as this will impact not only the type of machine you require but also its settings and functionalities.

Another crucial factor to evaluate is your production volume. Determine how much output your business expects to achieve daily or weekly. This will help in selecting a machine that not only meets your current capacity but can also scale as your business grows. Furthermore, examine the level of automation you desire; some machines offer advanced features like real-time monitoring and maintenance alerts, which can significantly enhance operational efficiency. By matching the machine's capabilities with your specific production requirements, you can make a more informed choice that supports your business goals.

Yarn Production Capacity Comparison

Key Features to Consider in Automatic Yarn Spinning Machines

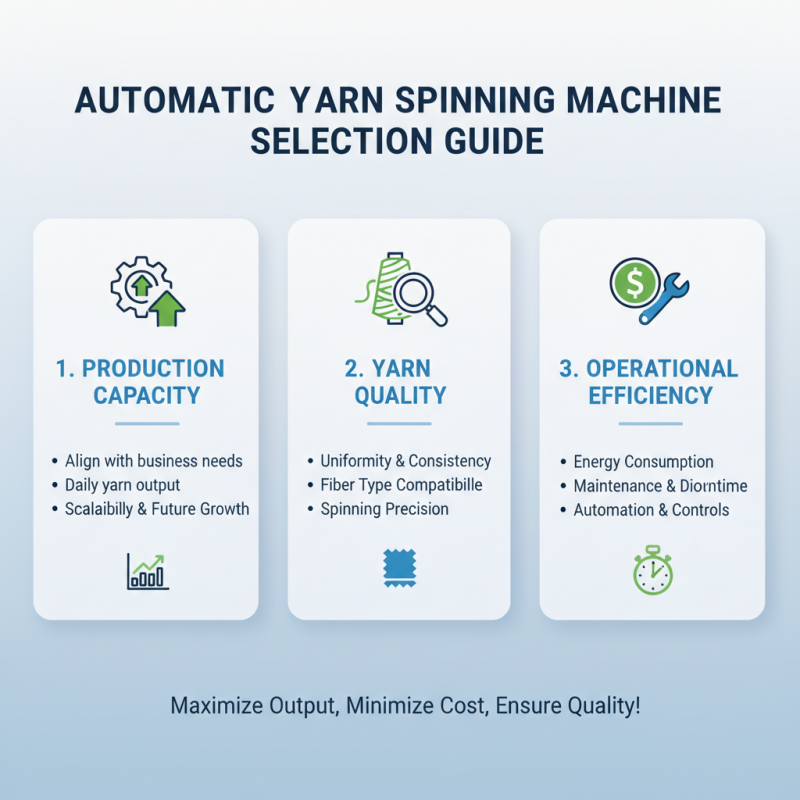

When selecting the ideal automatic yarn spinning machine for your business, it’s crucial to consider several key features that can enhance efficiency and quality. Firstly, the machine's production capacity should align with your business needs. Evaluate how much yarn you need to produce daily and choose a machine that can meet or exceed that requirement without compromising on quality.

Another important aspect is the type of fiber that the machine can process. If your business specializes in a certain type of fiber, such as cotton or synthetic blends, ensure that the spinning machine is designed to handle those specific materials. Additionally, features such as programmable settings, speed control, and ease of maintenance should not be overlooked. A machine with advanced technology will not only allow better control over the spinning process but also reduce downtime, thus maximizing productivity in your operations.

Evaluating Different Types of Yarn Spinning Technologies

When selecting the best automatic yarn spinning machine for your business, it’s essential to evaluate different types of yarn spinning technologies available in the market. Key technologies include ring spinning, open-end spinning, and air-jet spinning, each offering unique advantages and limitations. Ring spinning, renowned for its quality, produces fine and strong yarns but may also come with higher operational costs. In contrast, open-end spinning excels in processing shorter fibers and provides a quicker production rate, making it ideal for bulk production.

**Tips:** Consider the specific needs of your business when assessing these technologies. If quality is your top priority, investing in ring spinning may pay off in the long run. However, if speed and efficiency are crucial due to high demand, open-end spinning could be more beneficial. Additionally, evaluate the maintenance requirements and the availability of spare parts for each type of technology to ensure sustainability.

As you explore air-jet spinning, recognize its ability to create thick and fluffy yarns with less energy consumption. This process utilizes a unique mechanism that contributes to lower production costs and is gaining traction in industries focused on sustainability. Ultimately, aligning the strengths of each technology with your business goals will lead to a more informed decision when choosing the right spinning machine.

How to Choose the Best Automatic Yarn Spinning Machine for Your Business - Evaluating Different Types of Yarn Spinning Technologies

| Machine Type | Production Speed (m/min) | Yarn Types | Power Consumption (kW) | Weight (kg) | Price Range (USD) |

|---|---|---|---|---|---|

| Ring Spinning Machine | 120-300 | Cotton, Polyester | 15-20 | 1500 | 10,000 - 25,000 |

| Open-End Spinning Machine | 150-400 | Cotton, Blends | 20-25 | 2000 | 8,000 - 20,000 |

| Air Spinning Machine | 200-500 | Cotton, Wool | 25-30 | 2500 | 12,000 - 30,000 |

| Compact Spinning Machine | 100-250 | Cotton, Synthetic | 18-22 | 1600 | 15,000 - 35,000 |

Budgeting for Your Automatic Yarn Spinning Machine Investment

When considering the purchase of an automatic yarn spinning machine, effective budgeting is crucial for ensuring a successful investment. According to a recent industry report, the global yarn spinning machine market is projected to grow by approximately 4.5% each year, indicating an increasing demand for high-quality production equipment. As businesses navigate their budgets, it's essential to factor in not only the initial cost of the machinery but also the long-term expenses associated with maintenance, energy consumption, and workforce training.

Investors should be aware that the price range for automatic yarn spinning machines can vary significantly, typically from $20,000 to over $100,000, depending on the technology and capabilities offered. A detailed budget plan should encompass these variables, including the expected return on investment (ROI). For instance, advanced machines with higher production rates can lead to a quicker ROI, with studies indicating that companies adopting modern spinning technologies see up to a 30% reduction in production costs. Therefore, aligning budgetary constraints with the potential efficiencies gained from newer machines becomes vital in making informed decisions for future business growth.

Finding Reliable Suppliers and Manufacturers for Your Needs

Choosing the right supplier for your automatic yarn spinning machine is crucial for the success of your business. Reliable suppliers can greatly influence not only the quality of the machines but also the overall efficiency of your production processes. When searching for these suppliers, consider factors such as their reputation in the industry, the quality of their products, and their ability to provide excellent customer support. Engaging with well-established manufacturers can ensure that you receive high-quality machines that align with your production needs.

In addition to evaluating supplier legitimacy, it’s important to explore their manufacturing capabilities and lead times. Suppliers who leverage advanced technology and have robust supply chain management systems in place are likely to provide better service and support. It’s beneficial to seek references or case studies from other businesses that have partnered with these suppliers, as this can give insights into their reliability and product performance.

Focusing on these aspects while searching for a supplier will aid in making a well-informed decision, ultimately enhancing your business operations.

Related Posts

-

2025 Top 10 Yarn Manufacturing Machines: Boost Efficiency with Advanced Technology

-

How to Choose the Best Machine for Spinning Wool Based on Expert Data and User Reviews

-

Top 10 Best FDY Yarn Machines for High Quality Fabric Production

-

Unlocking the Art of Weaving: How Spinning Wool into Yarn Machines Transform Craftsmanship

-

What is Open End Spinning? Understanding Its Benefits and Applications in Textile Industry

-

Why You Should Invest in an FDY Yarn Machine for Your Textile Business Growth