How to Choose the Best Cotton Yarn Making Machine for Your Business Needs

Choosing the right cotton yarn making machine is a pivotal decision for any business involved in textile manufacturing. The quality of the yarn produced directly impacts the final product, influencing everything from texture to durability. As the textile industry continues to evolve, the demand for efficient and high-quality cotton yarn machines has grown significantly. It's essential for businesses to consider various factors before investing in a cotton yarn making machine to ensure it meets their specific operational needs.

When selecting a cotton yarn making machine, businesses should assess their production capacity, the types of cotton fibers they use, and the desired yarn characteristics. Additionally, factors such as machine efficiency, ease of operation, maintenance requirements, and available technology play crucial roles in the decision-making process. By thoroughly evaluating these aspects, companies can make informed choices that not only enhance their production capabilities but also align with their overall business strategy, ensuring a competitive edge in the market.

Understanding Your Business Requirements for Cotton Yarn Production

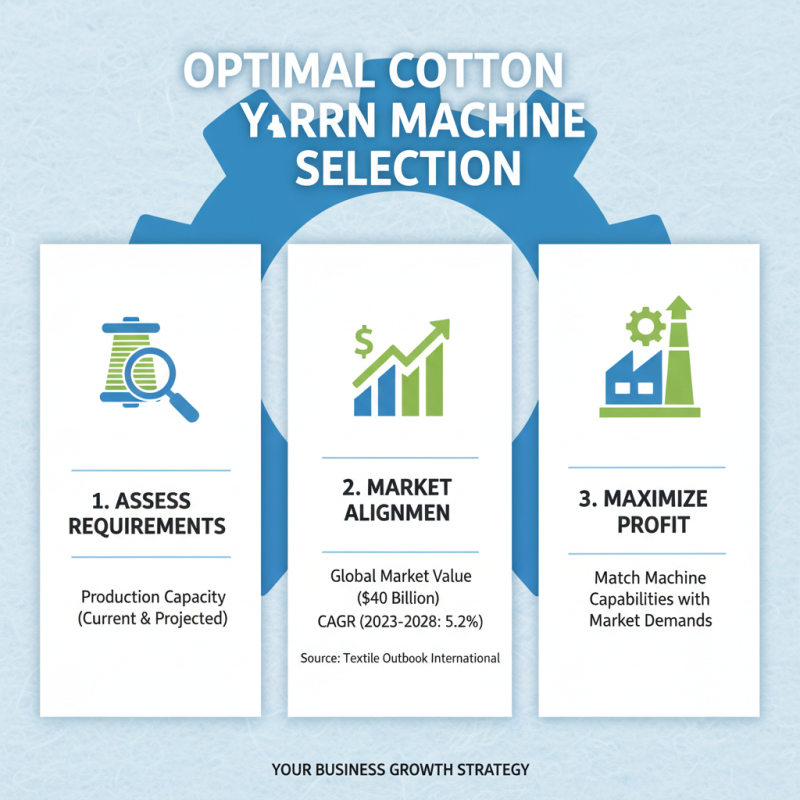

When selecting the best cotton yarn making machine for your business, it's crucial to first understand your specific production requirements. A detailed analysis of your current and projected yarn production capacity is essential. According to the Textile Outlook International report, the global cotton yarn market was valued at approximately $40 billion in 2022, and it is anticipated to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2028. This statistic underscores the importance of aligning your machine's capabilities with market demands to maximize profitability.

Moreover, consider the types and qualities of yarn you aim to produce. Different machines are tailored for specific yarn counts and blends. The International Textile Manufacturers Federation (ITMF) reports that the demand for high-quality, sustainable cotton yarns is increasing, particularly in the eco-conscious consumer sector. This trend demands machines with advanced technology capable of producing finer yarns while minimizing waste. Assessing these factors will allow you to select machinery that not only suits your current production goals but also provides the flexibility to adapt to future market trends.

Types of Cotton Yarn Making Machines Available in the Market

When choosing a cotton yarn making machine for your business needs, it’s crucial to recognize the different types available in the market. The two primary categories are ring spinning machines and open-end spinning machines. Ring spinning machines are known for producing finer and stronger yarns, making them suitable for high-quality textile production. On the other hand, open-end spinning machines are more efficient for bulk production, as they allow for a faster spinning process and can produce thicker yarns.

Tip: Consider your production capacity and the quality of yarn you aim to achieve when selecting between these types. If your focus is on premium textiles, investing in ring spinning may be more advantageous. However, if you are looking to mass-produce yarn for various applications, open-end machines could significantly enhance your output.

Another notable type is the air-jet spinning machine, which uses air currents for spinning the yarn. This method has gained popularity due to its speed and ability to produce yarn with a unique texture. It can be particularly beneficial for businesses looking to create specialized yarn for niche markets.

Tip: Evaluate the specific requirements of your product line. If versatility and texture are priorities, incorporating air-jet spinning machines might provide the competitive edge you need.

Types of Cotton Yarn Making Machines Available in the Market

Key Features to Look for in a Cotton Yarn Making Machine

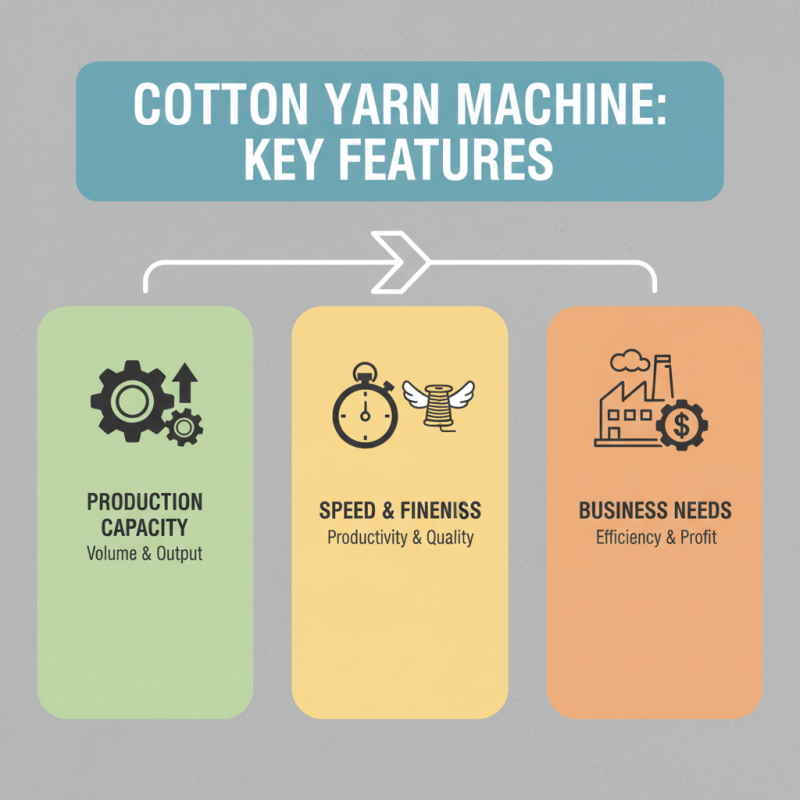

When selecting a cotton yarn making machine, there are several key features to prioritize to ensure it meets your business needs efficiently. First and foremost, consider the machine’s production capacity. Depending on your output demands, look for a machine that can handle the required volume of cotton yarn, whether for small-scale or large-scale operations. Additionally, pay attention to the machine's speed and the fineness of the yarn it can produce, as these factors will significantly impact your overall productivity and product quality.

Another critical aspect is the machine’s versatility. The ability to adjust settings for various yarn types and thickness is essential, allowing you to cater to different market demands and adapt to changing trends in the textile industry. Moreover, look for machines that feature user-friendly interfaces and automation capabilities which streamline the operational process, reducing the learning curve for your staff. Reliability and maintenance needs should also be evaluated; a machine that is easy to service and has readily available spare parts will save you time and reduce downtime in production. Essential features such as energy efficiency and reduced noise levels can further enhance operational sustainability, making it a smart investment for your business.

Evaluating Supplier Reputation and Machine Quality

When selecting a cotton yarn making machine, it’s crucial to evaluate both the supplier's reputation and the machine's quality. A reputable supplier often reflects reliability in their products and services. According to industry reports, approximately 45% of businesses face significant production setbacks due to poor equipment quality. This underscores the importance of researching suppliers who are recognized within the textile industry for their innovation and service. Look for suppliers with positive customer reviews, years of experience, and transparent communication regarding technical support.

When considering machine quality, focus on technical features that enhance operational efficiency and output. For instance, machines with energy-efficient motors can significantly reduce operational costs, as noted by a market analysis indicating that energy-efficient machinery can lower expenses by up to 30%. Additionally, machines with advanced automation features tend to minimize human error, improving overall productivity.

Tips:

- - Always request a demonstration of the machine and its features before making a purchase.

- - Verify the manufacturer’s warranty and after-sales support to ensure you have assistance when needed.

- - Investigate the availability of replacement parts to avoid long downtimes in the future.

Cost-Effectiveness and Return on Investment in Machine Selection

When selecting a cotton yarn making machine, it is crucial to analyze its cost-effectiveness and potential return on investment (ROI). According to industry reports, the initial investment in high-quality machinery often represents 15-25% of total production costs. However, the right machine can significantly reduce operational expenses by improving efficiency and decreasing waste. For instance, advancements in technology have led to machines that can operate with up to 20% less energy consumption compared to older models, translating directly into savings for businesses over time.

Furthermore, the projected lifespan of a cotton yarn making machine plays a pivotal role in determining its ROI. Recent studies suggest that modern machines can last up to 15 years with proper maintenance, providing manufacturers with an extended period to recoup their investments. The total cost of ownership should include not just the purchase price, but also maintenance, energy consumption, and production capacity. By comparing these factors, businesses can identify machines that offer the best long-term value, ultimately supporting sustainable growth in a competitive market where margins are often tight. Investing strategically now can yield significant benefits, making it essential for manufacturers to prioritize their operational needs and future scalability.

Related Posts

-

What is Open End Spinning? Understanding Its Benefits and Applications in Textile Industry

-

How to Choose the Best Automatic Yarn Spinning Machine for Your Business

-

Unlocking the Art of Weaving: How Spinning Wool into Yarn Machines Transform Craftsmanship

-

Why You Should Invest in an FDY Yarn Machine for Your Textile Business Growth

-

Why You Should Choose a Home Wool Spinning Machine for Your Crafting Needs

-

How to Choose the Best FDY Yarn Machine for Optimal Production Efficiency