How to Choose the Best FDY Yarn Machine for Optimal Production Efficiency

Choosing the right FDY yarn machine is a critical decision that can significantly influence production efficiency in the textile industry. With the increasing demand for high-quality fabrics, manufacturers face the challenge of selecting machinery that not only meets quality standards but also optimizes productivity. The FDY yarn machine plays a pivotal role in this equation, as it is specifically designed to produce fine denier yarns that are essential for creating lightweight, yet durable, textiles.

In a competitive market, understanding the features and capabilities of various FDY yarn machines can help manufacturers make informed choices that enhance their production processes. Factors such as machine speed, energy consumption, and ease of maintenance are vital considerations that contribute to overall efficiency. Additionally, advancements in technology have led to innovative designs that not only improve output but also reduce waste, further maximizing the potential of these specialized machines.

As businesses strive to achieve optimal production efficiency, the selection of an FDY yarn machine becomes paramount. This guide will explore key aspects to consider when choosing the best machine for your needs, ensuring that you can meet market demands while maintaining high production standards. By focusing on the right equipment, manufacturers can enhance their competitive edge and drive growth in the ever-evolving textile landscape.

Understanding FDY Yarn Machines and Their Importance in Production

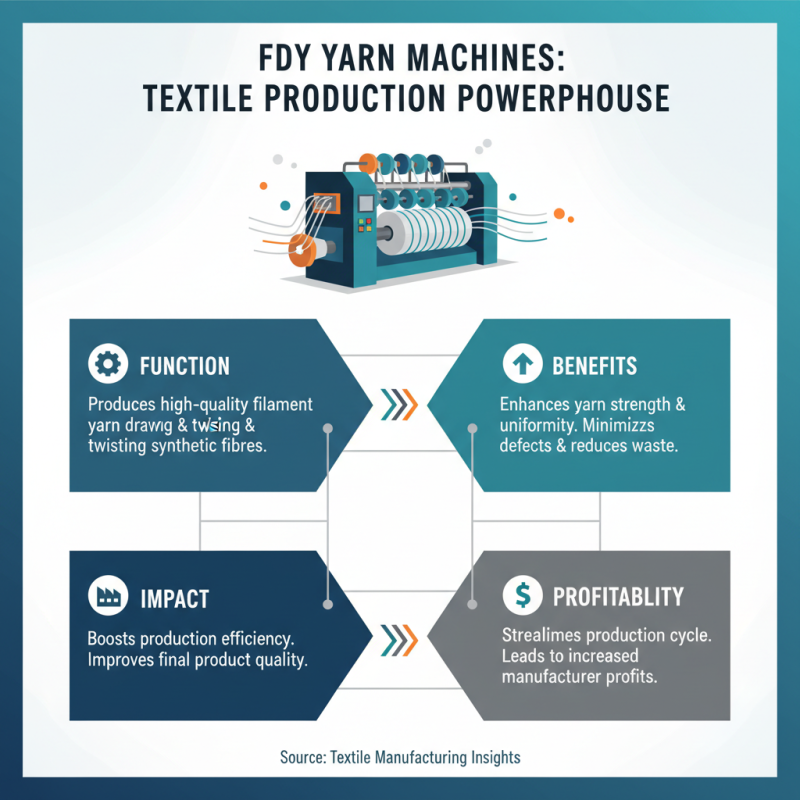

FDY yarn machines, or Fully Drawn Yarn machines, play a crucial role in the textile manufacturing process. These machines are designed to produce high-quality filament yarn by the process of drawing and twisting synthetic fibers, which enhances the strength and uniformity of the yarn. Understanding their operation is vital, as they significantly influence the overall production efficiency and quality of the final product. A well-functioning FDY yarn machine can minimize defects, reduce waste, and streamline the production cycle, leading to improved profitability for manufacturers.

The importance of FDY yarn machines in production cannot be overstated. They provide the necessary adjustment capabilities to accommodate various fiber types and thicknesses, enabling manufacturers to adapt to market needs quickly. The ability to produce consistent, high-strength yarn is vital for various applications in the textile industry, from apparel to industrial uses. Moreover, advancements in technology have led to innovations in these machines, increasing automation and efficiency, which significantly boosts output while reducing operational costs. Understanding these machines and their impact on production is essential for any textile producer aiming for optimal efficiency and product quality.

Key Factors to Consider When Selecting an FDY Yarn Machine

When selecting an FDY (Fully Drawn Yarn) yarn machine, several key factors must be considered to maximize production efficiency. One of the primary considerations is the machine's output capacity. According to a 2022 industry report, integrating high-speed technology can increase production rates by up to 30%, significantly reducing manufacturing time and costs. Additionally, machine energy efficiency plays a crucial role; machines that consume less power while maintaining performance can save manufacturers up to 15% in operational expenses over time.

Another essential factor is the flexibility of the machine to handle various yarn types and specifications. As market demand shifts towards specialized and sustainable yarns, selecting a machine that offers adaptability can enhance a production line's responsiveness to these changes. Recent market analysis indicates that companies investing in multi-function machines have reported an increase in overall production efficiency by approximately 25%, which reflects the growing importance of versatility in manufacturing processes.

**Tip:** When evaluating FDY yarn machines, always consider the machine’s maintenance requirements. A machine with easier access for repairs and parts replacement can minimize downtime significantly. Additionally, look for those equipped with advanced automation features. Such technologies can streamline operations, reduce human error, and further boost production efficiency.

Evaluating Production Capacity and Efficiency Metrics

When selecting an FDY (Fully Drawn Yarn) yarn machine, understanding production capacity and efficiency metrics is crucial. Recent industry reports indicate that optimal machines can achieve production speeds ranging from 800 to 1200 meters per minute, which significantly impacts overall throughput. Machines that can dynamically adjust spindle speeds based on material characteristics not only enhance production efficiency but also minimize waste, directly affecting the bottom line. According to a 2023 market analysis, companies utilizing advanced FDY machines reported up to a 20% increase in output due to improved operational efficiencies.

Additionally, evaluating the operational efficiency of an FDY yarn machine involves analyzing various performance indicators such as energy consumption, downtime, and maintenance needs. Data suggest that machines equipped with intelligent monitoring systems can reduce energy costs by 15-25%, further boosting productivity. Furthermore, machines that offer easier accessibility for maintenance tasks have been shown to decrease downtime significantly, with some manufacturers reporting reductions of over 30%. To maximize production efficiency, it is essential to select machines that combine high-speed capabilities with integrated technological features that streamline operations and lower total costs.

Analyzing Technology and Features of FDY Yarn Machines

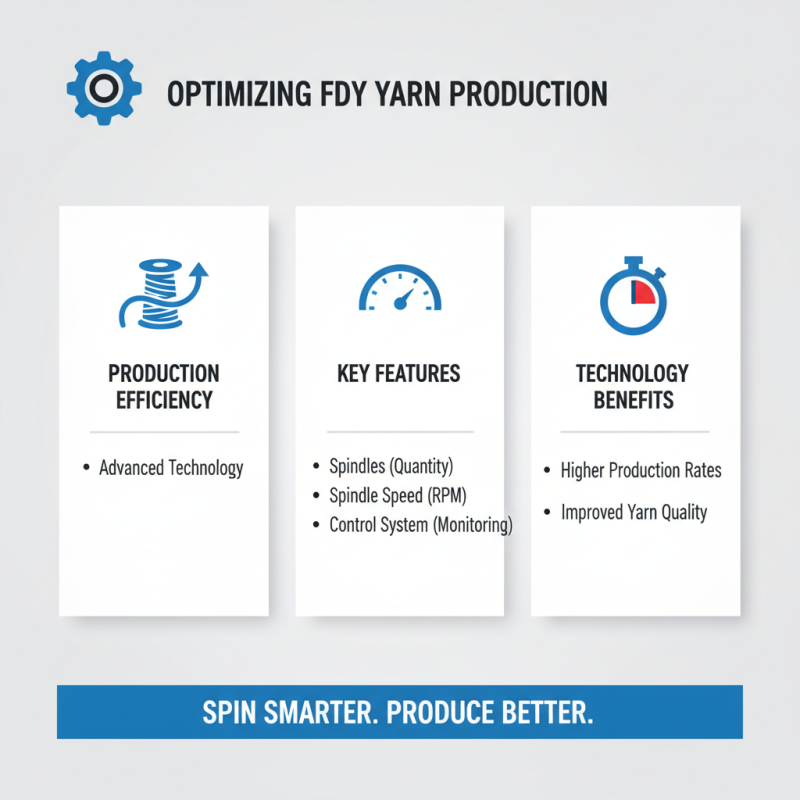

When selecting the best FDY yarn machine, understanding the technology and features that contribute to production efficiency is crucial. Advanced FDY yarn machines are equipped with modern technologies that enhance the overall performance of the spinning process. Key features to consider include the number of spindles, spindle speed, and the machine's control system. A higher spindle speed can significantly increase production rates, while an efficient control system allows for better monitoring and adjustments during the spinning process, resulting in higher-quality yarns.

Additionally, the machine's energy efficiency should not be overlooked. Machines designed with energy-saving technologies can reduce operational costs while maintaining high output levels. Features such as automated lubrication systems, optimized air flow, and integrated safety measures also play critical roles in maintaining machine longevity and reducing downtime. By focusing on these technological advancements, producers can ensure that they choose FDY yarn machines that not only meet their production needs but also contribute to overall operational efficiency.

Cost-Benefit Analysis of Different FDY Yarn Machines

When selecting the best FDY yarn machine, conducting a thorough cost-benefit analysis is crucial for determining optimal production efficiency. This analysis entails comparing various models, considering not only the initial purchase price but also operational costs, maintenance expenses, and energy consumption. A machine with a higher upfront cost may offer advanced features and better energy efficiency, leading to lower operating costs over time. Additionally, factors such as the machine's output capacity and speed should be considered, as these will influence overall productivity and profitability.

Another essential aspect of the cost-benefit analysis involves evaluating the potential return on investment (ROI). By analyzing the production speed and quality of different FDY yarn machines, manufacturers can project how quickly they will recoup their investment based on current market demands. Consideration should also be given to the longevity and reliability of each machine; investing in a durable model can minimize unexpected downtime and reduce the frequency of repairs, ultimately contributing to a smoother production process and sustained revenue generation.

Cost-Benefit Analysis of Different FDY Yarn Machines

Related Posts

-

Why You Should Invest in an FDY Yarn Machine for Your Textile Business Growth

-

Top 10 Best FDY Yarn Machines for High Quality Fabric Production

-

What is Open End Spinning? Understanding Its Benefits and Applications in Textile Industry

-

How to Choose the Best Machine for Spinning Wool Based on Expert Data and User Reviews

-

What is an Industrial Wool Spinning Machine and How Does It Work

-

Top 10 Spinning Machines for Yarn: An Ultimate Guide for Efficient Production