How to Choose the Best Poy Spinning Machine for Your Manufacturing Needs?

Choosing the right poy spinning machine is crucial for any textile manufacturer. The perfect machine can influence production speed, yarn quality, and overall efficiency. With many options available, finding the best fit is challenging. Each manufacturer has unique needs based on their product line, budget, and production scale.

Consider the specific requirements of your production. A large operation may need a high-capacity poy spinning machine. Smaller manufacturers might prioritize versatility over volume. Features like energy efficiency and ease of maintenance are also significant. Not all machines offer the same reliability, which can lead to unexpected downtime.

It’s important to seek expert advice. Speak with manufacturers and industry professionals. Analyze reviews and case studies. Understand what works and what doesn’t. Reflect on your own operations. Are there aspects that often lead to issues? Identifying these can guide your decision. Ultimately, the right choice can set the stage for success in your manufacturing journey.

Understanding Poy Spinning Machines and Their Applications in Manufacturing

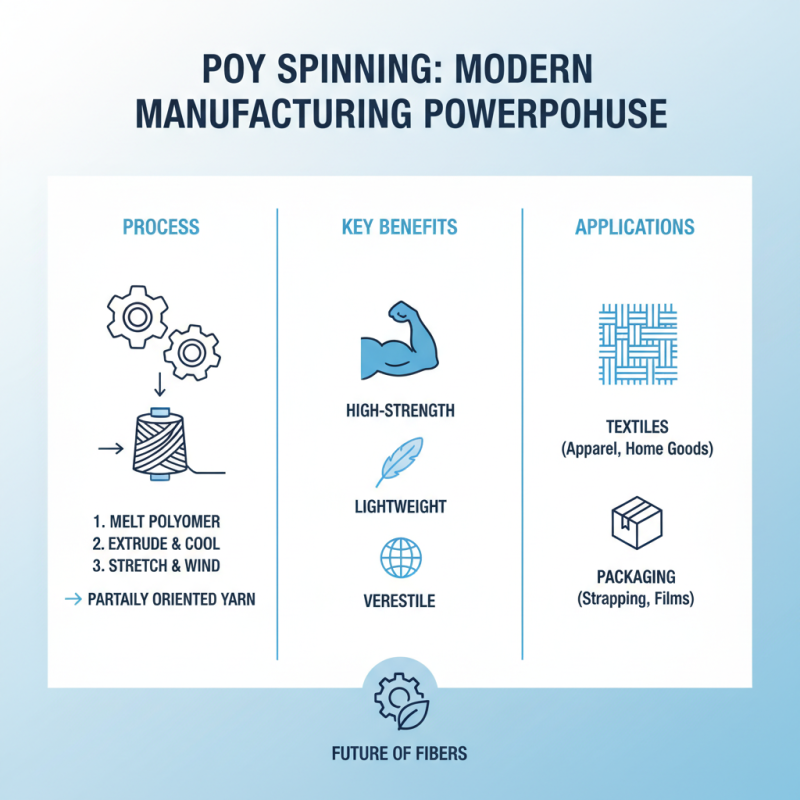

POY spinning machines play a vital role in modern manufacturing. These machines process polyester and other synthetic fibers through a method called "partially oriented yarn" spinning. This process allows for the production of high-strength, lightweight yarns used in various applications, including textiles and packaging. Understanding the technical aspects can help you make informed decisions.

In terms of applications, POY yarns are essential in fabric production. They are often used in sportswear, home textiles, and industrial applications. The versatility of these yarns is quite impressive. However, selecting the right machine can be overwhelming. Factors such as production speed, energy efficiency, and maintenance costs need careful consideration. Not all machines are equal, and the choice will impact your output quality.

One common oversight is ignoring the machine's adaptability. Some machines excel in specific applications but fall short in others. It's also critical to consider space requirements and power supply. A machine that fits your facility may not be the best performer. Ensure to review all specifications. Reflecting on past experiences with machinery may guide your selection process effectively.

Key Factors to Consider When Selecting a Poy Spinning Machine

Choosing the right POY spinning machine is crucial for your manufacturing process. One key factor is the machine's capacity. You need to assess your production volume. A machine with a higher capacity can save time and boost efficiency. However, it's essential to match this capacity with your actual needs. An oversized machine may lead to unnecessary costs.

Another important consideration is the machine’s energy consumption. An energy-efficient model can reduce operational costs in the long run. This factor may seem minor, but it has a significant impact on profitability. It's worth investigating the energy ratings of different machines. Don’t forget to think about your workspace. A larger machine may require more floor space, which could complicate your layout.

Additionally, look into the machine's ease of operation and maintenance. A user-friendly interface can improve productivity. Machines that are hard to maintain could lead to downtime. You might find that a simpler design works better for your team despite advanced features. Reflect on your specific needs and environment before making a choice. This step is often overlooked, yet it can make a big difference. Balancing all these factors is challenging, but it’s crucial for success.

Comparative Analysis of Different Poy Spinning Machine Models

When selecting the right POY spinning machine, a comparative analysis of various models is essential. Different machines come with unique features. Performance metrics, such as production speed and energy consumption, vary significantly across models. Industry reports indicate that modern machines can produce yarn with speeds up to 600 meters per minute. Efficiency impacts costs directly. Advanced models often feature automated threading, enhancing productivity but potentially increasing initial investment.

Tips: Evaluate energy efficiency ratios. Machines that consume less energy tend to have higher long-term savings. Check user reviews on machine reliability. Operational downtime can drastically affect production rates. Some operators report issues with specific models stalling frequently.

Consider versatility in yarn production. A machine that adapts easily to different materials can future-proof your manufacturing process. Some models excel in producing finer yarns, while others are better for thicker threads. Understanding the limitations of each type will help avoid costly mistakes. Data suggests that inefficient machines can result in up to a 30% increase in waste over time.

Evaluating Cost vs. Performance for Poy Spinning Machines

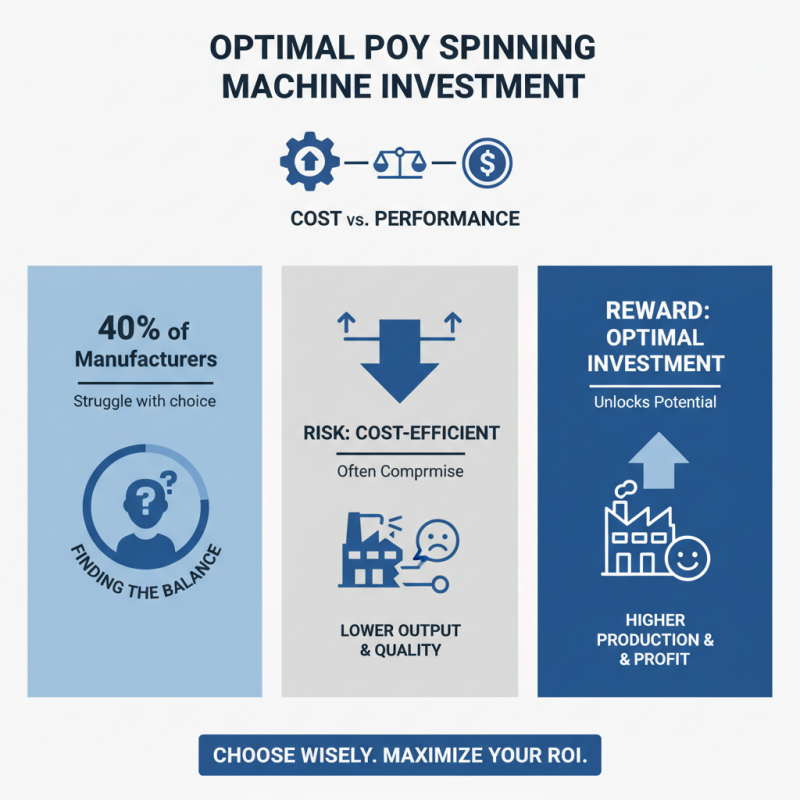

Choosing the right Poy spinning machine can significantly impact your manufacturing output. The balance between cost and performance is crucial. Recent industry reports indicate that around 40% of manufacturers face challenges when determining the optimal investment for their production needs. Cost-efficient machines may seem appealing, but they often compromise performance.

Performance is measured not just in speed but also in the quality of the yarn produced. A machine that operates at lower cost may yield only 70% of the desired yarn quality. This can lead to increased waste and rework, affecting overall profitability. Investing a bit more upfront can yield better efficiency and durability. Data shows that high-performance machines typically reduce maintenance costs by up to 20% over five years.

However, businesses must evaluate their unique needs. Lower demand for certain products could make high-end machines an overinvestment. Flexibility and scalability should also play a role in decision-making. Not all high-cost machines guarantee the best output for every type of yarn. Balancing these factors requires contemplation and a thorough analysis of potential returns. It's essential to reflect on both immediate and long-term impacts on your operations.

Maintenance Tips for Optimal Performance of Poy Spinning Machines

Maintaining Poy spinning machines is crucial for efficient operation. Regular checks on the machine's components are essential. Inspect the spindle regularly for any signs of wear or damage. If you notice any unusual noise, it might indicate an underlying issue.

Lubrication is vital. Use the recommended lubricant to keep the moving parts running smoothly. Over time, dust and debris can accumulate. Ensure to clean the machine thoroughly. This prevents unnecessary breakdowns and prolongs the lifespan of the equipment.

Employee training is often overlooked. Properly trained staff can execute maintenance tasks effectively. Encourage team members to report any irregularities. Ignoring small issues can lead to costly repairs later. Remember, a proactive approach to maintenance yields better performance overall.

Performance Comparison of Different POY Spinning Machines

Related Posts

-

Top 10 Spinning Machines for Yarn: An Ultimate Guide for Efficient Production

-

How to Choose the Best Automatic Yarn Spinning Machine for Your Business

-

How to Choose the Best Cotton Yarn Making Machine for Your Business Needs

-

What is a Machine for Spinning Wool and How Does It Work?

-

Why You Should Choose an Automatic Wool Spinning Machine for Your Business

-

Why You Should Choose a Home Wool Spinning Machine for Your Crafting Needs