2026 How to Choose the Best Automatic Wool Spinning Machine for Your Needs

In the rapidly evolving textile industry, selecting the right automatic wool spinning machine is crucial. According to a report by Technavio, the global automatic spinning machine market is expected to grow by 7% annually from 2021 to 2025. This growth highlights the rising demand for efficiency and quality in wool production.

Industry expert Dr. Emily Chen emphasizes, “Choosing an automatic wool spinning machine requires a balance between technology and production needs.” Her insight reflects a common challenge faced by manufacturers. They must navigate between budget constraints and the need for advanced features. Often, even high-quality machines fall short in user-friendliness.

As companies expand their production, the importance of tailored solutions becomes clear. Not all machines fit every producer’s unique requirements. Ignoring specific needs can lead to inefficiencies and increased costs. Understanding the intricacies of your production line is essential. It’s not simply about purchasing a machine; it’s about investing in the future of your business.

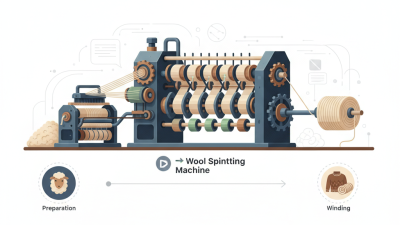

Understanding the Basics of Automatic Wool Spinning Machines

Choosing the right automatic wool spinning machine can be challenging. Understanding its features is vital for your decision. Each machine varies in size and capability. You need to consider how much wool you plan to spin. This will help you select the best option for your needs.

Tips: Focus on user-friendliness. Look for a machine that is easy to operate. Read reviews from other users. This can give you insights into functionality and performance.

The spinning process involves several stages. From fibers to yarn, each step matters. Look for machines that offer adjustable tension settings. This allows you to create different yarn thicknesses. Pay attention to the machine's speed as well. Higher speeds may lead to uneven results, which can be frustrating.

Tips: Test the machine if possible. Familiarize yourself with its functions. This will help you avoid common pitfalls. Remember, practice makes perfect. Your skills will improve over time. Consider the maintenance requirements as well. Some machines need regular cleaning to work efficiently.

Key Features to Consider in a Wool Spinning Machine

When choosing an automatic wool spinning machine, several key features are essential. One major aspect to consider is the machine's speed. A 2022 industry report indicates that spinning machines with higher RPM (Revolutions Per Minute) can produce yarn more quickly, improving overall efficiency. Machines with 1000 RPM or more can significantly reduce production time.

Another important feature is the ease of operation. User-friendly interfaces are crucial. Machines that allow for easy threading and tension adjustments help minimize downtime. According to surveys, operators prefer systems that require less training, which ultimately boosts productivity. Machines that are complex may lead to more errors. This could make the production process less efficient.

Capacity is also vital. Machines with larger bobbin sizes allow for longer continuous runs. However, a larger capacity can complicate the handling and maintenance of the machine. It's a balancing act. Some users report feeling overwhelmed by machines that are too advanced. It might be beneficial to consider a range of options before making a decision. Investigating all available features will ensure that the machine meets specific production needs effectively.

2026 How to Choose the Best Automatic Wool Spinning Machine for Your Needs - Key Features to Consider in a Wool Spinning Machine

| Feature | Description | Importance | Rating (1-5) |

|---|---|---|---|

| Speed Control | Allows adjusting of spinning speed based on fiber type. | High | 5 |

| Built-in Scales | Integrated scales for precise weight measurement of the yarn. | Medium | 4 |

| Automatic Doffing | Machine automatically replaces full bobbins without stopping. | High | 5 |

| User Interface | Easy-to-use touch screen for monitoring and controlling settings. | High | 4 |

| Size & Portability | Consider the dimensions and weight for easier transport. | Medium | 3 |

| Multi-Fiber Capability | Ability to spin different types of wool and fibers. | High | 5 |

| Energy Efficiency | Low energy consumption compared to traditional machines. | Medium | 4 |

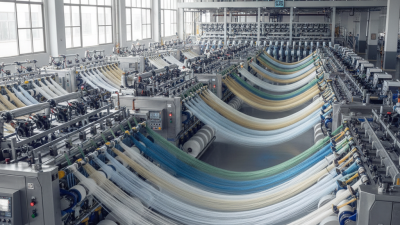

Evaluating Production Capacity and Efficiency Needs

When selecting an automatic wool spinning machine, production capacity is crucial. It’s essential to reflect on your specific needs. Think about the volume of wool you plan to process daily. A machine that is too small may lead to bottlenecks. Conversely, an oversized machine can increase operational costs without delivering extra value.

Efficiency also plays a significant role. Machines should minimize waste while maximizing output. Assess features like speed and energy consumption. Faster machines can improve productivity, yet they often require more upkeep. Striking a balance between speed and maintenance is vital.

Remember, no machine is perfect. Some may struggle with certain wool types. Research real user experiences to find common issues. It's also wise to remain open to adjustments in your operations. Adapting your workflow can compensate for any limitations the machine may have. This flexibility will ultimately enhance your production efficiency over time.

Assessing Cost and Budget for Your Wool Spinning Equipment

When choosing an automatic wool spinning machine, budget considerations are crucial. Determine how much you can realistically spend. Research shows that prices vary significantly. Basic models can start relatively low. However, advanced features will cost more. It’s essential to list your needs first. Prioritize functionalities that are necessary for your projects.

Consider all additional costs as well. Delivery fees, maintenance, and replacement parts can add up. Don’t overlook these expenses when calculating your total budget. Perhaps, set aside an extra 10% for unforeseen expenses. This flexibility can help you avoid financial strain. It’s not uncommon to feel overwhelmed by all the choices. Take your time and reflect on essential features. Evaluate your long-term needs versus immediate desires. Buying a machine is an investment, so ensure it aligns with your goals.

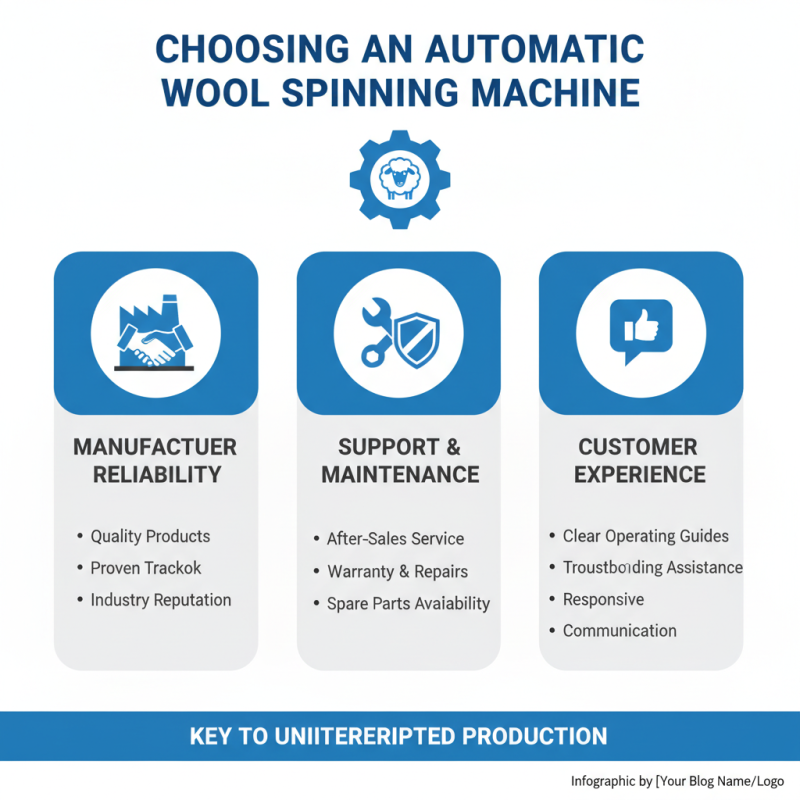

Maintenance and Support: Choosing a Reliable Manufacturer

When selecting an automatic wool spinning machine, the manufacturer's reliability is critical. A good manufacturer offers not just a quality product but also essential support and maintenance. Seeking a manufacturer known for excellent customer service can make all the difference in your work. You want to ensure they provide clear guidelines on operating and troubleshooting machinery.

Consider their warranty options. A generous warranty often indicates the manufacturer’s confidence in their machines. It can also save you from unexpected costs. Additionally, checking for regular maintenance schedules and availability of spare parts is vital. Without these, your machine could face prolonged downtime.

Don’t overlook user reviews and testimonials. They provide real-world insights into a manufacturer’s performance. Chat with other users to gather feedback. They might share experiences about service delays or maintenance issues. Take notes. It helps you make an informed decision that reflects your workplace realities.

Related Posts

-

Top 10 Best FDY Yarn Machines for High Quality Fabric Production

-

What is a Coir Spinning Machine and How Does It Work for Sustainable Products

-

What is an Industrial Wool Spinning Machine and How Does It Work

-

Top Yarn Manufacturing Machines for Efficient Production in 2023

-

How to Choose the Best Yarn Spinning Equipment for Your Needs

-

What is Open End Spinning? Understanding Its Benefits and Applications in Textile Industry