How to Choose the Best Fancy Yarn Making Machine for Your Projects?

Choosing the right fancy yarn making machine is crucial for project success. In recent years, the fancy yarn market has seen significant growth. According to a 2022 industry report, the demand for specialty yarns has increased by over 20%. This trend highlights the need for advanced machinery to produce unique and high-quality designs.

When selecting a fancy yarn making machine, consider various factors. Machine efficiency, versatility, and ease of use are vital. You might find that some models lack flexibility, limiting your creative options. Additionally, not all machines produce consistent results, which can be frustrating. A good machine should support innovation while maintaining quality.

Investing in a fancy yarn making machine can be overwhelming. The market offers many options with varying features and prices. It's essential to research and weigh your choices carefully. The right machine can elevate your projects, but the wrong one can lead you to disappointment. Always reflect on your specific needs and long-term goals.

Factors to Consider When Selecting a Fancy Yarn Making Machine

Choosing the right fancy yarn making machine involves careful consideration of various factors. First, assess the machine's capacity. Some machines handle small batches while others are designed for large-scale production. This difference can affect your workflow. Additionally, think about the types of yarn you want to create. Are you interested in textured, colored, or specialty yarns? Each type may require specific machine capabilities.

Next, consider the ease of use. Machines can vary in complexity, which may impact your learning curve. If you’re new to yarn making, a user-friendly design could save you time. Look for features like simple controls and clear instructions. Maintenance is another crucial aspect. Some machines require regular upkeep, while others are more low-maintenance. This can affect your long-term productivity.

Lastly, budget constraints play a significant role. Higher-end machines offer advanced features but may not fit every budget. Reflect on your project goals and how frequently you plan to use the machine. Sometimes, a mid-range model might meet your needs without excessive spending. Balancing these factors is essential, yet it can lead to difficult decisions. Prioritize what matters most to you in your crafting journey.

Types of Fancy Yarn Making Machines and Their Functions

When selecting a fancy yarn making machine, understanding the various types available is essential. Different machines serve distinct functions suited to diverse yarn designs. For example, there are texturing machines that add unique surface effects to the yarn. This creates a more dynamic texture, enhancing visual appeal. These machines often utilize heat and pressure to manipulate synthetic fibers, producing fascinating results.

Another category includes novelty yarn machines. These focus on creating unique blends of fibers, colors, and textures. The diversity allows for endless possibilities in design. However, they can be more complex. Operators may need time to learn the intricacies of controlling yarn thickness and twist. This could lead to mistakes. It's crucial to practice before committing to large projects.

Finally, specialized winding machines play a significant role. They prepare the yarn for knitting or weaving by ensuring even tension and neat packaging. However, choosing the right machine can be tricky. If a machine isn’t compatible with your goals, it can be frustrating. Reflecting on your specific needs is vital for making the best choice.

How to Choose the Best Fancy Yarn Making Machine for Your Projects?

| Type of Fancy Yarn Machine | Function | Production Capacity (kg/hr) | Power Consumption (kW) |

|---|---|---|---|

| Twisting Machine | Twists multiple strands of yarn together to create unique textures. | 50 | 10 |

| Warping Machine | Prepares yarn to be woven by creating parallel strands. | 70 | 12 |

| Knitting Machine | Interlocks yarn to form fabric through various knitting techniques. | 100 | 15 |

| Crochet Machine | Creates fabric by interlocking stitches using a hook. | 40 | 8 |

| Spinning Machine | Converts fiber into yarn by twisting it together. | 150 | 25 |

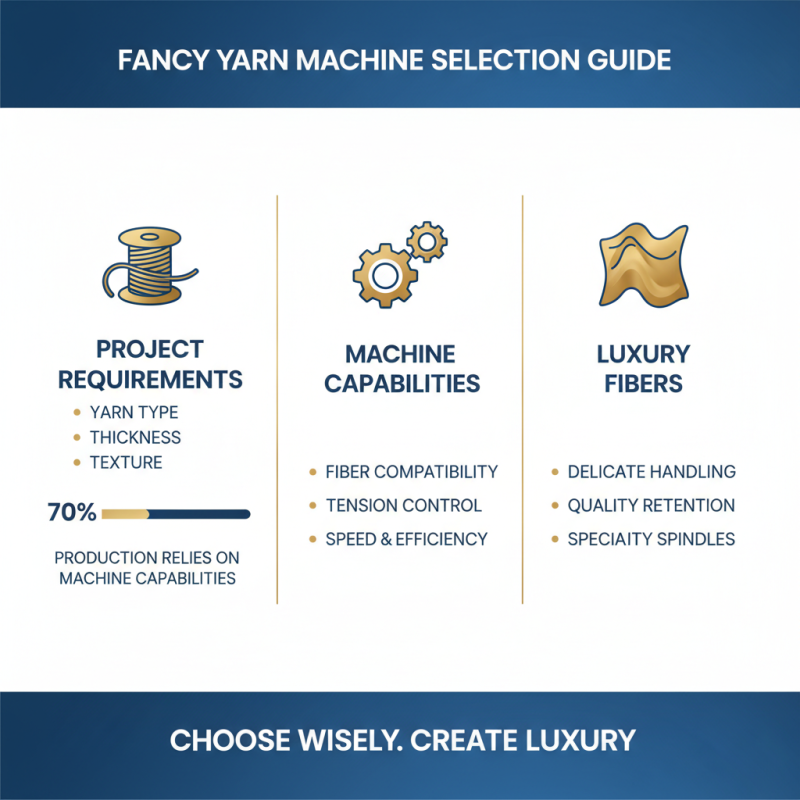

Understanding Your Project Requirements for Yarn Production

When selecting a fancy yarn-making machine, it's crucial to understand your project requirements. Various projects demand different yarn types, thicknesses, and textures. According to industry reports, 70% of yarn production relies on specific machine capabilities. If your project seeks luxury fibers, ensure your machine can handle delicate yarns without compromising quality.

**Tip:** Evaluate your project's scale. Will it be for small handmade items or large manufacturing? Different scales may require different machines.

Different applications require varied production speeds. Some machines can produce up to 1,200 yards of yarn per hour, while others may only manage a few hundred. This discrepancy can significantly impact delivery times and overall efficiency. Factor in whether you need customization for colors and patterns.

**Tip:** Test small batches first. This helps prevent costly mistakes when scaling up production. Reflect on the machine's versatility. Overly specialized machines may not adapt well to changing project needs. Understanding these elements can help improve decisions in machine selection.

Budgeting for Your Fancy Yarn Making Machine Purchase

When budgeting for a fancy yarn making machine, it’s essential to do thorough research. Understand the price range that suits your needs. Prices can vary significantly based on features and capabilities. Set a realistic budget that includes not just the machine’s cost, but also any necessary accessories.

Consider potential ongoing costs, like maintenance and spare parts. Sometimes, people forget about these expenses. They focus solely on the initial price. Additionally, think about your skill level. A more complex machine might be appealing but could lead to frustration. Know your limits. Will you really use all the features, or will they complicate your projects?

Don’t rush this decision. It’s easy to feel overwhelmed by options. Take your time to weigh the pros and cons. Reflect on what projects you plan to create. This clarity will help guide your decision. Avoid the shiny appeal of the latest models if they don’t fit your needs. Make sure every dollar spent aligns with your goals.

Maintenance and Support Considerations for Yarn Making Equipment

When selecting a fancy yarn making machine, maintenance is crucial. According to a recent industry report, machines require regular upkeep to ensure optimal performance. Neglecting this can lead to costly downtimes and repairs. A well-maintained machine can last up to a decade or more, providing a solid return on investment.

It's essential to consider the availability of technical support. Many manufacturers do not offer comprehensive assistance after sale. The report indicates that 30% of users experience difficulties without proper support. Training staff on routine maintenance tasks can mitigate issues and enhance machine longevity. Simple steps like cleaning and lubrication are often overlooked but vital.

Users should also reflect on the cost of spare parts. In some cases, parts may become scarce, driving prices up. A lack of accessibility can hinder project completion. Regular check-ups can identify small issues early. Failing to address minor problems might lead to bigger challenges later. Thus, investing in a machine with good maintenance support is often wise.

Related Posts

-

Top 10 Best PP Multifilament Yarn Machines for Efficient Production

-

Top 10 Benefits of Eri Silk Spinning Machines for Sustainable Production

-

Why You Should Choose a Home Wool Spinning Machine for Your Crafting Needs

-

How to Choose the Best Machine for Spinning Wool Based on Expert Data and User Reviews

-

Top Yarn Manufacturing Machines for Efficient Production in 2023

-

How to Choose the Best Automatic Yarn Spinning Machine for Your Business