How to Choose the Right FDY Yarn Machine for Your Production Needs?

Choosing the right FDY yarn machine is crucial for textile manufacturers. The demand for high-quality filament yarns is growing rapidly. According to a recent industry report, the global market for FDY yarn is expected to reach $7 billion by 2025. This trend highlights the importance of selecting the right machinery to meet production needs.

Manufacturers face several choices when it comes to FDY yarn machines. Different machines offer varying capabilities. Factors such as production speed, energy efficiency, and yarn quality should be considered. Many companies struggle to balance speed with quality. Failing to optimize this balance can lead to production delays and increased costs.

Investing in the right FDY yarn machine requires an understanding of current market demands. It's not just about purchasing the most expensive model. Manufacturers must assess their specific needs. This includes considering factors like maintenance and operational costs. A machine that seems perfect on paper may not perform well in real-world situations. Therefore, careful evaluation is essential to avoid potential pitfalls in production efficiency and output quality.

Identifying Your Production Requirements for FDY Yarn Machines

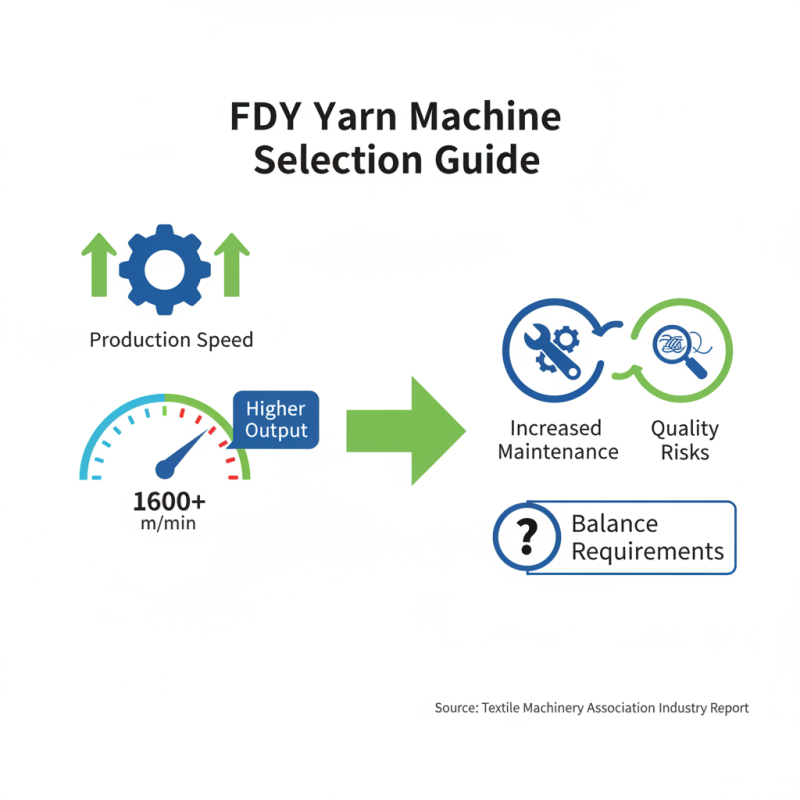

When selecting an FDY yarn machine, understanding your production requirements is crucial. An industry report from the Textile Machinery Association highlights that production speed is one of the key factors influencing machine selection. Higher speeds, often exceeding 1600 meters per minute, can significantly boost outputs. However, this comes with potential risks like increased maintenance needs and quality control issues.

Production capacity must align with your demand. If your business forecast indicates a need for 500 tons per month, consider machines that can reliably achieve such targets. For instance, models that offer flexibility can switch between different yarn types quickly. This is vital for adapting to market trends.

Labor considerations play a role too. Advanced machines, while efficient, may require skilled operators. A report from the Global Textile Analysis stressed the importance of training to maximize machine potential. Choosing a machine that balances efficiency with user-friendliness can mitigate challenges associated with operator skill gaps. In the end, reflect on these factors to ensure that your choice supports long-term production goals.

Understanding Different Types of FDY Yarn Machines Available

When selecting an FDY yarn machine, understanding the types available can significantly impact production efficiency. FDY yarn machines typically come in two main categories: single and double. Single machines are simpler but may limit your production volume. Double machines handle larger quantities and offer more versatility, making them suitable for varied applications.

Tips to consider: Evaluate your production capacity before purchasing. A machine that produces 1300 denier might not suit your needs if you're aiming for finer yarn. Additionally, think about the maintenance requirements. Some machines need more upkeep than others, which could lead to hidden costs.

Different types of FDY machines come with unique features. Some may include advanced automation, reducing labor costs. However, they might be complex for new users. It's crucial to gauge user-friendliness when making your choice. Wider machines might save time but can lead to increased waste if not managed well. Reflect on what works best for your team.

Evaluating Key Features to Consider When Selecting a Machine

When selecting an FDY yarn machine, it's essential to evaluate key features that impact your production. One critical aspect is the machine’s output capacity, which can vary significantly. For example, a high-capacity machine may produce up to 1000 kg of yarn per day. This could exponentially enhance production if your volume demands are high.

Another vital consideration is the energy efficiency of the machine. Recent reports indicate that energy-efficient models can reduce operational costs by up to 30%. Such savings are crucial in an industry where profit margins can be tight. However, one must also weigh these savings against the initial investment cost.

The ease of maintenance is often overlooked. Machines that require frequent servicing can lead to downtime. Even a slight delay in production can be costly. Studies suggest that maintenance issues can halt operations for about 10% of the total production time. It’s also important to consider the learning curve for operators. A complicated machine could require extensive training, slowing down the production ramp-up. It's beneficial to seek a balance between advanced features and user-friendliness to avoid lost time and resources.

Production Needs for FDY Yarn Machines

Assessing Cost vs. Performance in FDY Yarn Machine Selection

Choosing the right FDY yarn machine for your production can be challenging. Cost and performance are critical factors. Industry reports suggest that machines with higher initial costs often yield better efficiency and durability. For instance, a reputable study indicates that companies investing in advanced FDY machines can see a 30% increase in production efficiency over five years.

Tips: Always evaluate the total cost of ownership. Don't only focus on purchase price. Maintenance and operational costs can add up. A cheaper machine may lead to higher long-term expenses.

Performance metrics, such as speed and energy consumption, must also be considered. Machines that operate at higher speeds can produce more yarn in less time. However, they may consume more energy. Some reports show that energy-efficient machines reduce costs by up to 20%. It's essential to find a balance that meets your production requirements without overspending.

Tips: Conduct a thorough analysis of your production needs. Sometimes, a mid-range machine can provide the best value. Efficiency is not just about speed; it’s about sustainability too. Consider how each machine's performance affects your overall production strategy.

How to Choose the Right FDY Yarn Machine for Your Production Needs?

| Machine Model | Production Capacity (kg/h) | Energy Consumption (kW) | Maintenance Cost ($/year) | Performance Rating (1-10) | Estimated Cost ($) |

|---|---|---|---|---|---|

| Model A | 200 | 25 | 1200 | 8 | 25000 |

| Model B | 250 | 30 | 1000 | 9 | 30000 |

| Model C | 150 | 20 | 800 | 7 | 20000 |

| Model D | 300 | 35 | 1500 | 10 | 35000 |

| Model E | 220 | 28 | 1100 | 8 | 28000 |

Reviewing Maintenance and Support Options for FDY Yarn Machinery

When selecting FDY yarn machinery, maintenance and support are crucial. Proper maintenance keeps the machines running smoothly. Consider the availability of spare parts. It’s vital to have a reliable source. Downtime can be costly. Smooth operations depend heavily on this aspect.

Training and support are also important. Check if the manufacturer offers on-site training sessions. Knowledgeable staff can detect issues early. Regular check-ups may help avoid major repairs. Think about the technical support provided after purchase. Quick assistance can minimize production delays.

Reflect on the long-term relationship with suppliers. Quality support can enhance productivity. Communication is key here. Evaluate how responsive they are to inquiries. A solid partnership can lead to better outcomes. Always plan for unexpected challenges. Prepare for maintenance as you would for production needs.

Related Posts

-

How to Choose the Best FDY Yarn Machine for Optimal Production Efficiency

-

Top 10 Best FDY Yarn Machines for High Quality Fabric Production

-

Why You Should Invest in an FDY Yarn Machine for Your Textile Business Growth

-

What is Open End Spinning? Understanding Its Benefits and Applications in Textile Industry

-

10 Best Spinning Machines for Yarns to Increase Production Efficiency by 30 Percent

-

Top 10 Best PP Multifilament Yarn Machines for Efficient Production