What is a Coir Spinning Machine and How Does It Work for Sustainable Products

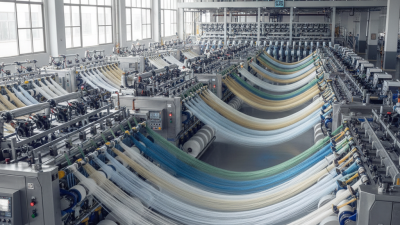

Coir spinning machines have emerged as innovative tools in the production of sustainable products derived from coconut husk fibers. As the world increasingly turns to eco-friendly materials, the significance of coir spinning machines cannot be overstated. These machines play a vital role in transforming raw coir fibers into high-quality yarns and textiles, providing a sustainable alternative to synthetic fibers that often harm the environment.

In an era marked by the need for sustainable practices, coir spinning machines are at the forefront of revolutionizing the textile industry. By harnessing the natural strength and durability of coir, manufacturers can create a variety of products, from mats and ropes to filling materials and textiles, all while minimizing ecological impact. The process involves several steps, including fiber extraction, cleaning, and spinning, each of which showcases the machine's efficiency and the quality of the final product.

This overview delves into the workings and benefits of coir spinning machines, highlighting how these devices contribute to sustainability and the growing market for eco-friendly products. As industries and consumers alike seek greener alternatives, understanding the functionality and importance of coir spinning machines becomes essential for anyone interested in sustainable manufacturing processes.

The Role of Coir Spinning Machines in Sustainable Manufacturing Practices

Coir spinning machines play a crucial role in

sustainable manufacturing practices by transforming coconut husk fibers into valuable products.

These machines utilize an eco-friendly process that minimizes waste and maximizes resource efficiency.

The technology enables the extraction of fibers from coco coir, which are then processed into yarn or rope, making them suitable for a variety of applications,

from home textiles to automotive interiors. By leveraging coir, manufacturers can reduce their reliance on

synthetic materials, thus promoting a circular economy.

Furthermore, the operation of coir spinning machines aligns with sustainability principles by ensuring

minimal environmental impact. The production process is designed to utilize renewable resources, as

coconut palms are abundant in tropical regions and have a low carbon footprint. Additionally, the waste

generated during fiber extraction can be repurposed as organic fertilizer or biomass fuel, contributing to

zero waste initiatives.

By integrating coir spinning machines into their production lines, businesses not only enhance their

sustainability credentials but also support local economies and promote responsible sourcing of materials.

Key Components and Mechanisms of Coir Spinning Technology

Coir spinning machines are essential for transforming coconut husk fibers into sustainable yarns used in various eco-friendly products. The key components of these machines include the fiber extraction units, spinning frames, and winding devices. The fiber extraction unit, often comprising a defibrillator, separates the coir fibers from the husk, preparing them for further processing.

The mechanisms within the coir spinning technology play a crucial role in ensuring efficiency and quality. Modern machines utilize advanced control systems that monitor tension and speed, optimizing the spinning process. Additionally, the use of biodegradable lubricants minimizes environmental impact, making the entire operation more sustainable.

The winding device then collects the spun yarn, readying it for use in the production of eco-friendly mats, ropes, and textiles. By harnessing these technologies, manufacturers can produce high-quality coir products that support sustainability while also meeting the growing demand for green alternatives in various industries.

Benefits of Using Coir Fiber in Eco-friendly Products

Coir fiber, derived from the husk of coconuts, has gained significant traction in the eco-friendly products market due to its numerous benefits. According to a report by the Global Coir Market Analysis, the coir fiber industry is projected to grow by 12% annually as consumers increasingly seek sustainable alternatives to synthetic materials. Coir is biodegradable, durable, and resistant to saltwater, making it an ideal choice for a range of applications, from gardening products to household items.

One of the standout advantages of using coir fiber is its moisture retention capacity. This natural fiber retains moisture better than many synthetic counterparts, promoting healthier plant growth in gardening applications. Moreover, coir products contribute to soil aeration and reduce the need for chemical fertilizers, aligning perfectly with sustainable agriculture practices. By integrating coir fiber into eco-friendly products, manufacturers can not only support environmental sustainability but also offer consumers high-quality, durable alternatives that reduce environmental footprints.

**Tips for Using Coir Products:** When opting for coir-based products, ensure you select items that are sourced sustainably. Look for certifications that verify eco-friendly practices in coir production, such as organic certification. Additionally, consider using coir mulch in your garden for enhanced moisture retention while minimizing weed growth. This way, you support sustainable practices while nurturing your plants effectively.

Coir Fiber Usage in Eco-friendly Products

Future Trends in Coir Spinning Machines and Sustainable Solutions

As the demand for sustainable products continues to rise, the

coir spinning machine industry

is undergoing significant transformation. The global market for coir products is expected to grow at a

CAGR of 12%

from 2021 to 2026, driven by increasing awareness of environmental issues and the need for biodegradable alternatives to synthetic materials. Coir, derived from coconut husks, provides an eco-friendly solution for various applications, from textiles to agricultural products.

Future trends in coir spinning machines focus on enhancing efficiency and reducing waste through innovative technologies.

For instance, advancements in automation and smart manufacturing processes can lead to higher production rates while minimizing energy consumption. Reports indicate that integrating IoT solutions into coir spinning machinery can improve monitoring and maintenance processes, leading to a more sustainable production cycle.

Tips: When exploring sustainable solutions, consider investing in coir products that are certified organic or fair trade. Such certifications not only ensure sustainability but also support ethical production practices. Additionally, always evaluate the entire life cycle of products to understand their environmental impact fully and make informed purchasing decisions. Embracing these insights can significantly contribute to a greener future.

Comparative Analysis: Coir Spinning vs. Traditional Fiber Production Methods

Coir spinning machines represent a transformative approach to producing sustainable fibers from coconut husks, positioning themselves as a competitive alternative to traditional fiber production methods. Traditional methods often rely on significant water and chemical inputs, whereas coir spinning leverages the natural resilience and durability of coconut fibers, which are inherently eco-friendly. According to industry projections, the vegetal natural fiber market, which encompasses materials like coir, is expected to grow at a significant rate, reflecting increasing consumer demand for sustainable products. Reports indicate that by 2034, the market for vegetal natural fibers, including coir, is poised to expand considerably, underscoring the shift towards more sustainable materials.

In contrast to traditional fiber production, which can include cotton and synthetic fibers requiring intensive pesticide and water use, coir spinning utilizes waste materials effectively, contributing to zero-waste practices. The innovative processing of lignin waste into high-value products like carbon nanotube fibers also exemplifies the potential for renewable biomass materials to play an essential role in sustainable development. The growth potential of coir and other vegetal fibers not only highlights their eco-friendly attributes but also the pressing need for industries to pivot towards sustainable practices that reduce environmental impact while fostering economic growth in the renewable materials sector.

What is a Coir Spinning Machine and How Does It Work for Sustainable Products - Comparative Analysis: Coir Spinning vs. Traditional Fiber Production Methods

| Criteria | Coir Spinning Machine | Traditional Fiber Production |

|---|---|---|

| Resource Sustainability | High (Uses coconut husk, a byproduct) | Variable (Depends on source, e.g., cotton) |

| Energy Consumption | Lower (More efficient machinery) | Higher (More labor-intensive methods) |

| Production Speed | Moderate to High | Low to Moderate |

| Waste Generation | Minimal (Uses most of the coconut husk) | High (Cotton production has significant waste) |

| Product Durability | High (Natural resistance to salt and water) | Variable (Dependent on fiber type) |

| Market Demand | Increasing (Growth in eco-friendly products) | Stable (Traditional demand remains) |

Related Posts

-

Unlocking the Art of Weaving: How Spinning Wool into Yarn Machines Transform Craftsmanship

-

2025 Top 10 Yarn Manufacturing Machines: Boost Efficiency with Advanced Technology

-

Top 10 Best FDY Yarn Machines for High Quality Fabric Production

-

Why You Should Invest in an FDY Yarn Machine for Your Textile Business Growth

-

10 Best Spinning Machines for Yarns to Increase Production Efficiency by 30 Percent

-

What is Open End Spinning? Understanding Its Benefits and Applications in Textile Industry