How to Use a Coir Yarn Spinning Machine Effectively for Your Projects?

In today's eco-conscious world, the coir yarn spinning machine stands out as an innovative tool for crafting sustainable products. This machine transforms coconut husks into durable coir yarn, ideal for various projects. Using it effectively can enhance your creativity and productivity.

Many users face challenges when operating the coir yarn spinning machine. It requires practice to achieve the desired quality. Adjusting tension, for instance, can make a significant difference. A slight mistake can ruin the whole batch. Understanding the machine's intricacies is essential for maximizing its potential.

Moreover, optimizing the spinning process can lead to better results. Experimenting with different materials can provide unique textures. Some users find it rewarding to create accessories or decorative items. Yet, every project has its learning curve. Embrace the imperfections; they can guide you towards improvement.

Understanding the Basics of Coir Yarn Spinning Machines

Coir yarn spinning machines are essential in the textile industry, particularly for eco-friendly products. These machines convert raw coir fiber into strong, durable yarn. According to a 2022 industry report, the coir product market is projected to grow by 12% annually. This growth highlights the rising demand for sustainable materials.

Operating a coir yarn spinning machine requires a good understanding of its components. Ensure that the fiber is clean and free of debris. Incorrect handling can lead to a low-quality end product. Maintenance is crucial. Regularly check tension settings and replace broken parts promptly to avoid downtimes. Improper adjustments can cause uneven spins, affecting yarn quality.

It’s important to experiment with different settings. Each batch of coir fiber may behave differently. The moisture content can significantly impact spinning. Incomplete drying can lead to issues like tangling. Recording observations helps improve future processes. Attention to detail can yield better results. Learn from mistakes, and make adjustments to refine your technique.

Choosing the Right Coir Yarn Spinning Machine for Your Needs

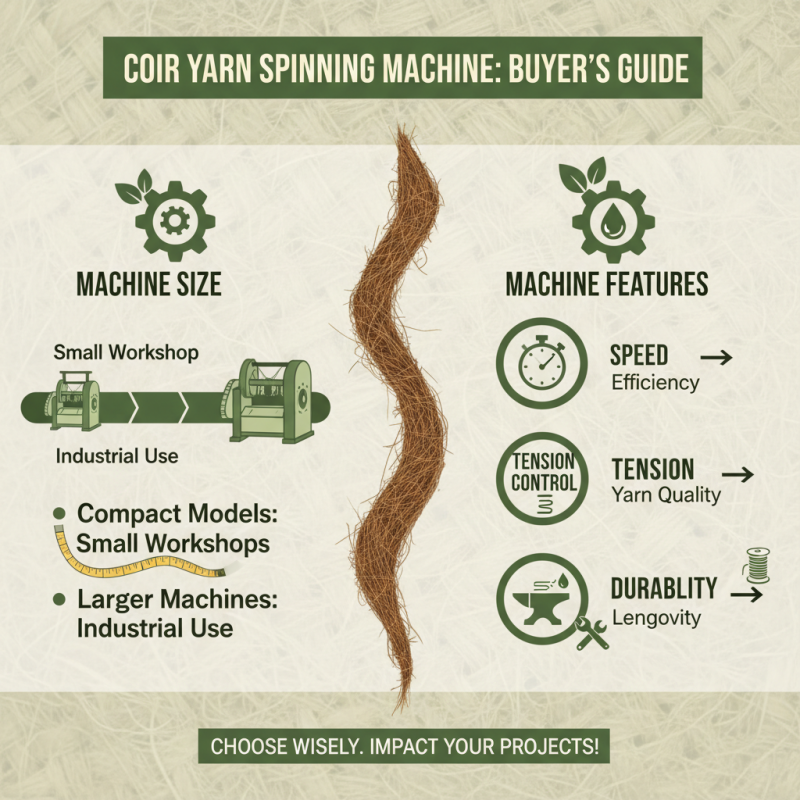

Choosing the right coir yarn spinning machine can significantly impact your projects. Consider the size of the machine. A compact model is ideal for small workshops. Larger machines may suit industrial use. Evaluate the machine’s features. Think about speed, tension control, and durability. These aspects affect the quality of your yarn.

Next, assess your project needs. Are you making rugs, mats, or decorative items? Different projects require varying thread thicknesses. Ensure the machine you choose can handle your requirements. Don’t overlook the ease of use. Some machines might have complicated setups. A straightforward design saves time and frustration.

Also, think about maintenance. Machines with fewer parts often mean easier care. Repairs can be a hassle. Reflect on the training required. Some machines may need skilled operation, which might not be available. Consider whether you can acquire that skill. Making the right choice takes effort and reflection.

Setting Up Your Coir Yarn Spinning Machine Properly

Setting up your coir yarn spinning machine properly is crucial for optimal performance. A well-organized workspace can boost productivity. According to industry reports, around 70% of inefficiencies in production stem from poor setup. Begin by placing the machine on a stable surface to reduce vibrations. Ensure that all parts are correctly aligned to avoid operational hiccups. A misaligned machine can waste valuable time and material.

Next, pay attention to tension settings. The yarn must be spun at an appropriate tension to prevent breaks. Studies indicate that improper tension can result in a 30% increase in defects. Regularly checking and adjusting tension is a necessary step many overlook. Keep tools handy for quick adjustments.

Lighting is another often-neglected factor. Insufficient light can lead to mistakes during setup and operation. Ensure your workspace is well-lit to maintain focus. Likewise, encourage regular breaks to prevent fatigue. Remember that a fresh mind can significantly improve setup efficiency. Small reflections on these aspects can help refine your process and avoid common pitfalls in yarn production.

How to Use a Coir Yarn Spinning Machine Effectively for Your Projects? - Setting Up Your Coir Yarn Spinning Machine Properly

| Dimension | Details |

|---|---|

| Machine Type | Coir Yarn Spinning Machine |

| Power Requirement | 1 HP |

| Production Capacity | 50 kg/day |

| Operational Speed | 200 RPM |

| Coir Fiber Length | 10-12 inches |

| Maintenance Frequency | Monthly |

| Key Features | Adjustable tension, user-friendly controls |

| Typical Applications | Rope making, mat production, crafts |

Effective Techniques for Operating a Coir Yarn Spinning Machine

Operating a coir yarn spinning machine can be effortless with the right techniques. Start by ensuring that your workspace is clean and organized. A tidy area reduces distractions. It's crucial to familiarize yourself with the machine's specific parts. Each component plays a vital role in yarn production.

Tips: Check the tension settings regularly. Too loose or too tight can ruin your yarn. Always have spare parts on hand. This helps avoid delays during projects.

Pay attention to the quality of coir fibers you use. Low-quality fibers can lead to inconsistent yarn thickness. It's also essential to monitor the spinning speed. Fast speeds may seem efficient but can cause defects. Take your time to find a balance that works for your project.

Tips: Keep a log of your operations. Note what works well and what doesn’t. Reflection can reveal hidden patterns. Don’t hesitate to adjust your methods as necessary. Adapting is key to mastering coir yarn spinning.

Production Efficiency of Coir Yarn Spinning Machine

This chart illustrates the monthly production efficiency of a coir yarn spinning machine. The data represents the total kilograms of coir yarn produced from January to June, highlighting the increase in production capacity over these months.

Maintenance Tips for Long-lasting Coir Yarn Spinning Machine Performance

Maintaining a coir yarn spinning machine is crucial for optimal performance. Regular maintenance can extend the lifespan of the machine significantly. Reports indicate that machines maintained properly can last up to 30% longer. Dust and debris can accumulate in the machine parts. This buildup affects functionality and can lead to costly repairs.

Daily checks should become a routine. Inspect the belts and spindles for wear. Lubricate moving parts frequently to ensure smooth operation. Neglecting these steps can lead to breakdowns. An alarming 20% of breakdowns are due to inadequate maintenance. It’s vital to clean the machine after each use, especially if working with natural fibers. This helps to minimize damage from dirt.

Periodic professional inspections can prevent small issues from escalating. However, some operators may overlook this step, believing they can do it all. It's important to recognize that expert evaluations can reveal potential failure points. A minor fix now saves significant costs in the future. Ignoring maintenance leads to inefficiencies and can halt production completely. Focusing on these aspects enhances productivity and machine longevity.

Related Posts

-

What is Open End Spinning? Understanding Its Benefits and Applications in Textile Industry

-

How to Choose the Best Automatic Yarn Spinning Machine for Your Business

-

How to Choose the Best FDY Yarn Machine for Optimal Production Efficiency

-

Top 10 Spinning Machines for Yarn: An Ultimate Guide for Efficient Production

-

What is a Yarn Manufacturing Machine and How Does It Work?

-

Top 10 Tips for Choosing the Right PP Multifilament Yarn Machine