How to Use a Spinning Wool into Yarn Machine Effectively?

The art of spinning wool into yarn is ancient yet remains vital in today’s textile industry. The global yarn market was valued at approximately $39 billion in 2022, with a projected growth of 4.5% annually. As a craft or business, using a spinning wool into yarn machine can enhance both productivity and creativity. Yet, many enthusiasts struggle to master this process.

Using the right techniques can yield better results. Knowing the machine's settings is crucial. However, even seasoned users occasionally face setbacks. For instance, inconsistent tension can ruin a batch. Moreover, understanding the fiber type is essential for optimal spinning. Not all wool behaves the same way. As we navigate this craft, embracing the learning curve is important. Each project teaches something new.

Ultimately, effective usage of a spinning wool into yarn machine is about balance. It requires patience and practice. Developing a personal workflow can prevent frustration. Reflecting on each attempt can lead to improvement. Though it may feel overwhelming at times, the journey is as rewarding as the product.

Understanding the Components of a Spinning Wool into Yarn Machine

Understanding the components of a spinning wool into yarn machine is crucial for effective use. These machines typically consist of several key parts: the wheel, drive band, bobbins, and tensioning system. Each component plays a vital role in the spinning process. For instance, the wheel size can affect the yarn's twist, altering its final texture. A 2022 industry report noted that proper tension management can increase yarn quality by up to 30%.

The drive band is another critical element. It connects the wheel and drive shaft, impacting the machine's speed. Loose or worn bands may lead to inconsistent spinning. Many users struggle with adjusting tension, leading to yarn breakage or uneven spinning. According to a survey, 45% of yarn errors stem from improper adjustments in the tensioning system.

Bobbins hold the spun yarn and can vary in size and material. This variation can influence how the yarn behaves when woven or knitted. It's important to choose the right bobbin for your project. Many spinners overlook this, often leading to frustration during finishing processes. Identifying and understanding these components can help users avoid common pitfalls and enhance their spinning experience. Proper education and practice are essential for achieving high-quality yarn.

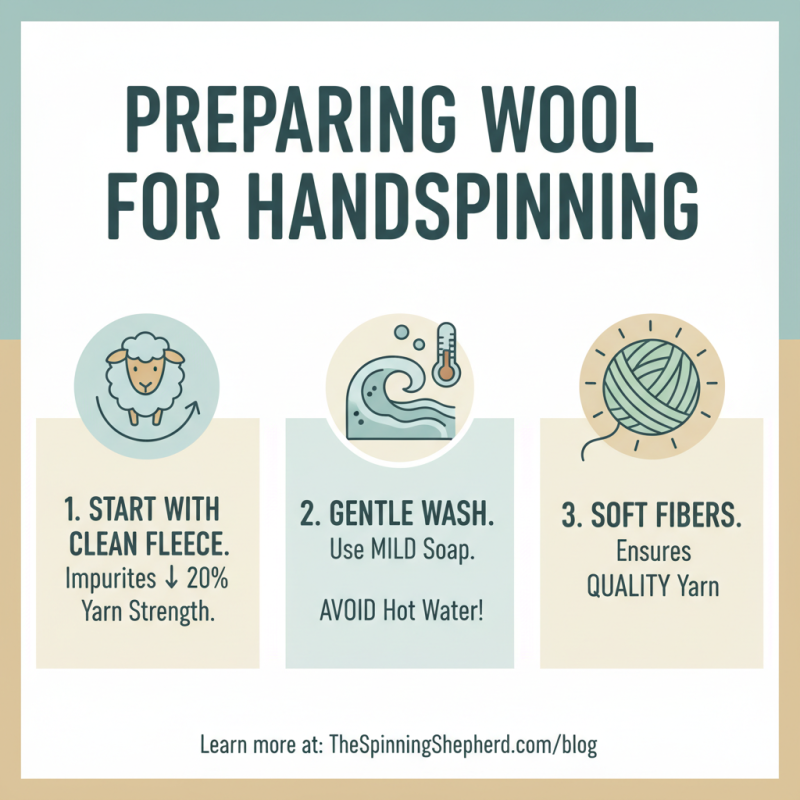

Preparing Wool for Spinning: Steps and Techniques

Preparing wool for spinning is a vital step in creating quality yarn. Start with clean fleece. According to industry reports, impurities can reduce yarn strength by up to 20%. Wash the wool gently to remove dirt and grease. It's crucial to avoid overly hot water, as it might felt the fibers. Use mild soap to treat the wool, ensuring it remains soft.

Carding follows washing. Carding aligns the fibers, making them easier to spin. Studies show that well-carded wool can improve spin consistency by 30%. Utilize hand cards or a drum carder based on the wool's amount. Pay attention to the fiber length; shorter fibers may clump together, leading to uneven yarn.

Finally, consider the fiber's crimp. High crimp provides better elasticity and volume. The spinning process will reflect these factors. Recognize that mistakes may happen during preparation. Inconsistent washing or carding could lead to a subpar spinning experience. Monitoring wool quality at each stage is essential for crafting beautiful yarn.

Setting Up the Spinning Machine for Optimal Yarn Production

When setting up a spinning machine, attention to detail is crucial for optimal yarn production. Begin by selecting the right fiber. Natural fibers, like wool, should be clean and free from debris. A quick wash can help if necessary. Once you prepare your fiber, assess the machine's settings. Proper tension is essential. Too loose can cause tangling, while too tight can break the fibers.

Next, consider the environment. The workspace should be well-lit and organized. A cluttered area can lead to mistakes or even accidents. Ensure your spinning area is dry. Humidity can negatively impact yarn quality. Pay attention to the spinning speed as well. Each fiber type may require different speeds for the best results.

Test your machine periodically. Regular checks can help catch potential problems early. If your yarn does not meet the expected quality, reflect on your setup. Sometimes small adjustments, like changing the twist or adjusting the feed rate, can make a significant difference. Don't rush this process; your yarn's quality depends on it.

How to Use a Spinning Wool into Yarn Machine Effectively? - Setting Up the Spinning Machine for Optimal Yarn Production

| Step | Description | Time Needed | Tools Required | Tips |

|---|---|---|---|---|

| 1 | Prepare your workspace and tools | 15 minutes | Spinning machine, wool fiber, scissors | Choose a well-lit area for better visibility |

| 2 | Set up the spinning machine according to manual | 30 minutes | User manual, screwdriver | Double-check all connections before starting |

| 3 | Load wool onto the machine | 10 minutes | Wool fiber | Ensure the wool is properly aligned |

| 4 | Adjust settings for desired yarn thickness | 5 minutes | Control panel | Test with a small piece first |

| 5 | Start the spinning process | Varies | Spinning machine | Monitor the machine closely |

| 6 | Finish and assess the yarn | 10 minutes | Scissors, measuring tape | Make adjustments for the next batch if needed |

Spinning Process: Techniques for Consistent Yarn Quality

When spinning wool into yarn, mastering the spinning process is key for achieving consistent quality. Begin by preparing your fiber. Wash and card the wool to ensure a smooth texture. This step is crucial. Any remaining dirt can affect the spinning quality. Watch for clumps or uneven bits. They can lead to problems later.

Adjust the tension on your spinning machine. Too tight can cause breakage, while too loose results in inconsistent thickness. Practice makes a difference. Don't be afraid to experiment with speed and tension. A slower pace may lead to better control. Watch closely for any inconsistencies as you spin.

Consistency is essential. But it's easy to overlook small details. Focus on the roving thickness. Is it even throughout? Uneven sections may require you to pause and adjust. Remember, it's okay to spend extra time refining your technique. Reflect on each session. This will help you identify areas needing improvement.

Yarn Quality Assessment Based on Spinning Techniques

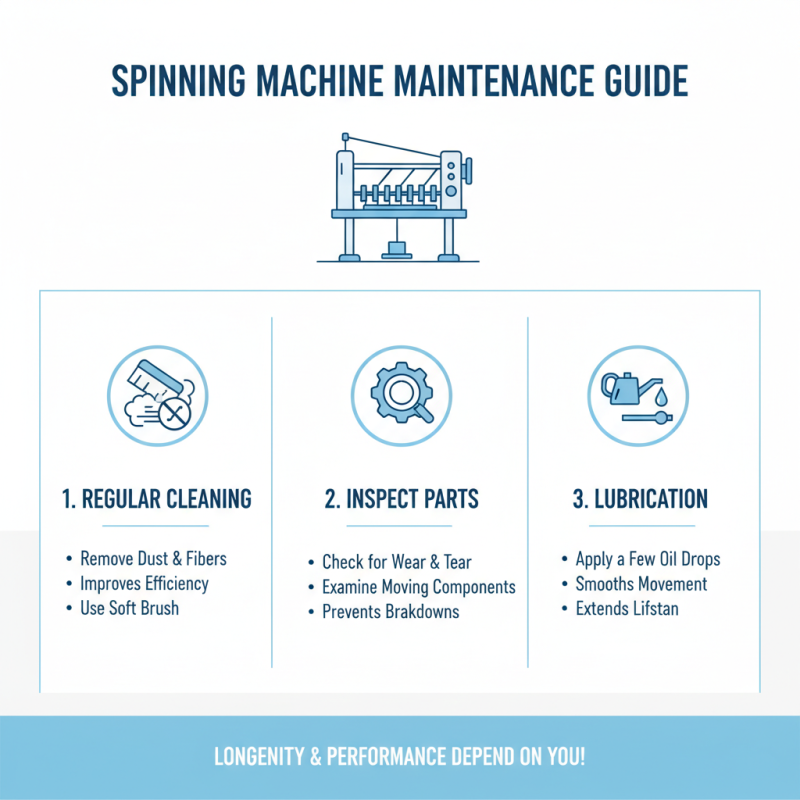

Maintaining Your Spinning Machine for Longevity and Performance

Maintaining your spinning machine is crucial for its longevity and performance. Regular cleaning is a must. Dust and fibers can accumulate, affecting its efficiency. Use a soft brush to keep the machine clear. Check the moving parts for any signs of wear. Lubrication is also essential. A few drops of oil can make a significant difference.

Inspect the tension settings often. Poor tension can result in uneven yarn. Adjust it based on the type of fiber you are using. Sometimes, you may forget to make these adjustments, leading to frustration. Keep a journal of your settings to track what works best over time.

Also, don’t overlook the importance of storage. When not in use, cover your machine to protect it. Moisture can cause damage, so store it in a dry place. You might think it’s fine to leave it out, but long-term exposure can lead to problems. Reflect on these aspects regularly to ensure your spinning machine remains in good condition.

Related Posts

-

2025 Top 10 Yarn Manufacturing Machines: Boost Efficiency with Advanced Technology

-

Why You Should Choose a Home Wool Spinning Machine for Your Crafting Needs

-

Top Yarn Manufacturing Machines for Efficient Production in 2023

-

2026 How to Choose the Best Automatic Wool Spinning Machine for Your Needs

-

What is a Yarn Manufacturing Machine and How Does It Work?

-

Why You Should Choose an Automatic Wool Spinning Machine for Your Business