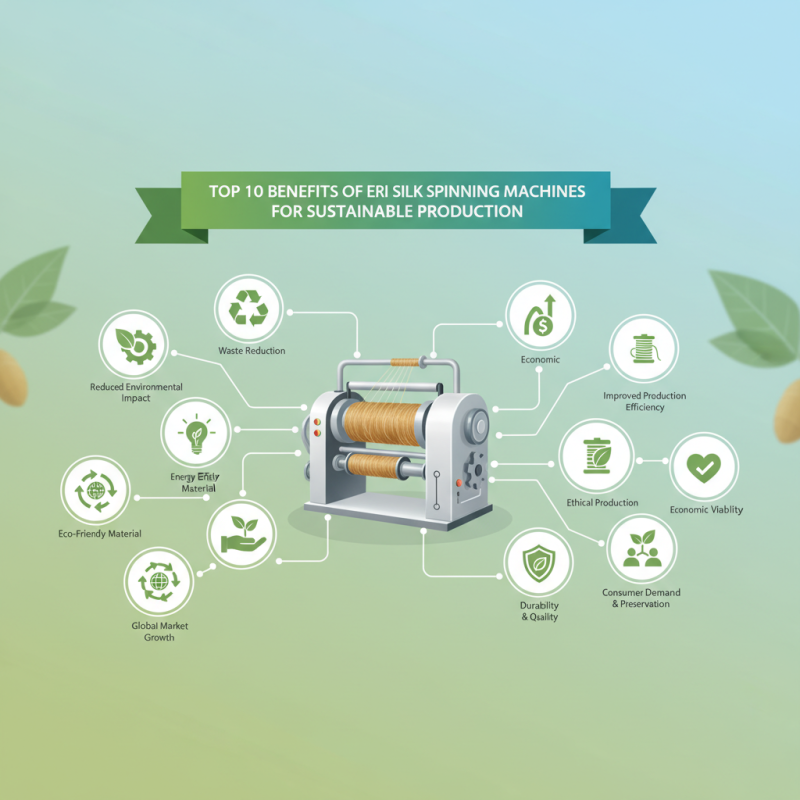

Top 10 Benefits of Eri Silk Spinning Machines for Sustainable Production

The textile industry has seen a growing shift towards sustainable practices in recent years, particularly with the increasing demand for eco-friendly materials. Among these materials, eri silk stands out due to its unique properties and lower environmental impact compared to conventional silk. Eri silk, derived from the Eri silkworm, is not only known for its durability and warmth but also its promise of sustainability, which is becoming increasingly significant in today's market. The adoption of advanced technologies, specifically eri silk spinning machines, plays a crucial role in enhancing the production efficiency and sustainability of this natural fiber.

Recent studies indicate that the global silk market is projected to reach USD 18.3 billion by 2027, with a considerable portion attributed to sustainable silk production methods. Eri silk spinning machines are designed to optimize the spinning process, reduce waste, and conserve energy, thereby aligning with the industry's shift towards sustainability. By implementing these machines, producers can not only meet the rising consumer demand for ethical silk products but also significantly contribute to environmental preservation. As the industry evolves, the benefits of eri silk spinning machines are becoming increasingly evident, promising not just economic viability but also a commitment to sustainable production.

Benefits of Eri Silk Spinning Machines for Eco-Friendly Textile Production

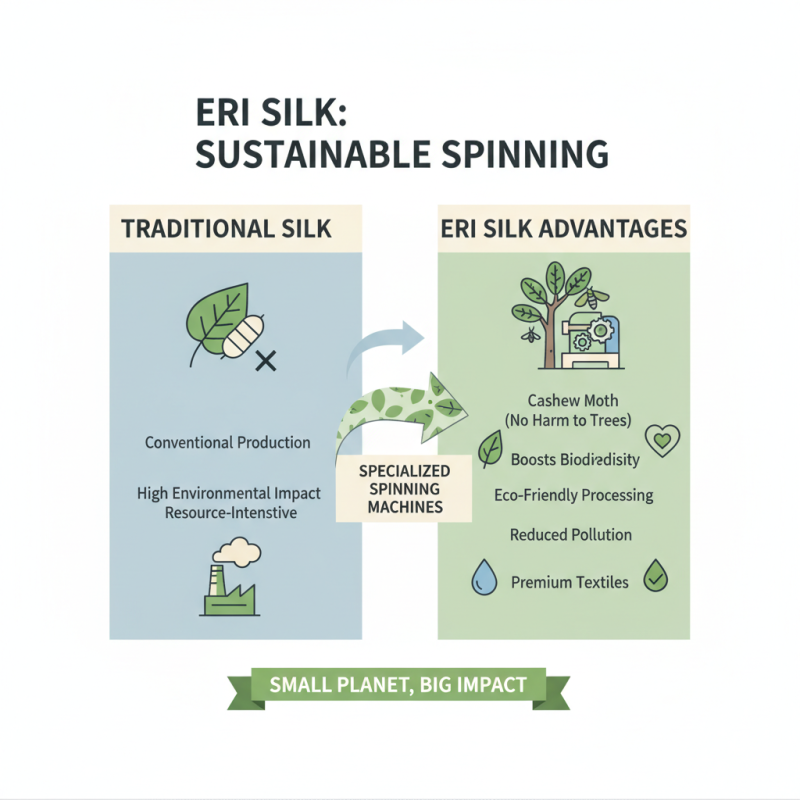

Eri silk, known for its sustainability, offers numerous benefits when spun using specialized spinning machines. One significant advantage is the reduction of environmental impact compared to conventional silk production. Eri silk is derived from the cashew tree silk moth, which feeds on leaves without harming the tree. This cycle creates a habitat that encourages biodiversity, making the process more ecologically friendly. By utilizing Eri silk spinning machines, manufacturers can produce high-quality textiles while ensuring minimal adverse effects on the environment.

Moreover, these spinning machines are designed to optimize resource efficiency. They require less energy and water than traditional silk production methods, leading to lower operational costs and reduced carbon footprints. The technology employed in Eri silk spinning enhances yarn strength and reduces waste during the spinning process. This refinement not only supports sustainable practices but also meets the growing consumer demand for eco-friendly textiles. As fashion trends shift towards sustainability, adopting Eri silk spinning machines represents a proactive approach to align production methods with environmentally conscious values.

Enhanced Fiber Quality: How Eri Silk Machines Improve Output Efficiency

Eri silk, known for its unique properties and environmental benefits, has gained attention in the textile industry as a sustainable alternative to conventional silk. The introduction of Eri silk spinning machines has significantly enhanced fiber quality and output efficiency in production processes. According to industry reports, these machines can increase fiber yield by up to 30% compared to traditional spinning methods. This improvement is due to advanced technology that optimizes the spinning process, allowing for finer fiber refinement and better strain control during production.

Furthermore, the integration of Eri silk spinning machines not only boosts efficiency but also reduces waste. As highlighted in recent studies, the automation and precision engineering in these machines contribute to minimizing excess fiber loss, translating to higher profitability and sustainability. Selective breeding and the machine's capability to handle varying fiber thicknesses ensure that manufacturers can meet diverse market demands more effectively.

**Tips for Maximizing Efficiency**: To get the most out of Eri silk spinning machines, it's crucial to train operators thoroughly on the intricacies of the machinery. Proper maintenance and regular calibration will ensure optimal performance, leading to sustained high-quality output. Additionally, incorporating a sustainable sourcing strategy for raw materials can enhance the overall impact of Eri silk production, appealing to eco-conscious consumers.

Top 10 Benefits of Eri Silk Spinning Machines for Sustainable Production

This bar chart illustrates how Eri silk spinning machines enhance fiber quality and output efficiency across various benefits.

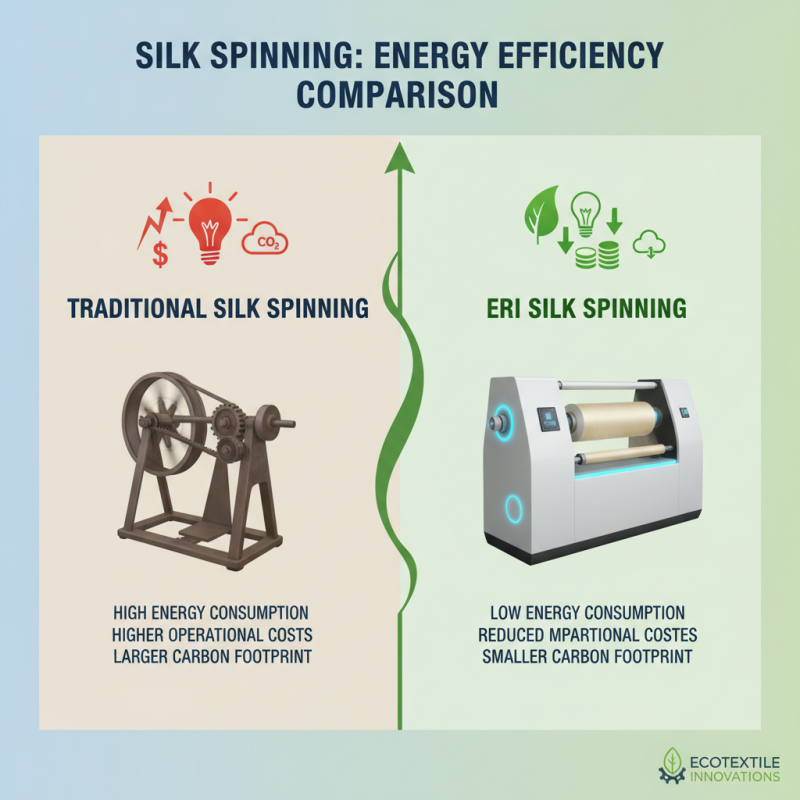

Energy Efficiency: Comparing Eri Silk Machines to Traditional Spinning Equipment

Eri silk spinning machines stand out in terms of energy efficiency when compared to traditional spinning equipment. Traditional methods often require significant energy inputs, leading to higher operational costs and a greater environmental impact. In contrast, Eri silk machines are designed with advanced technology that optimizes energy consumption, allowing for a more sustainable production process. By utilizing energy-efficient motors and systems, these machines reduce electricity usage, which not only lowers production costs but also minimizes the carbon footprint associated with silk manufacturing.

Moreover, the integration of innovative automation processes within Eri silk spinning machines enhances their energy performance. These machines can operate at higher speeds with less wasted energy, enabling them to produce silk more effectively while maintaining quality. The ability to monitor and adjust energy usage in real-time further supports sustainability, making Eri silk an attractive option for eco-conscious producers. Ultimately, the shift towards energy-efficient spinning processes not only benefits manufacturers economically but also supports broader environmental goals by reducing the overall energy demand in the textile industry.

Reduction of Waste in Sustainable Production: Eri Silk Technology's Role

Eri silk technology is rapidly emerging as a cornerstone in the quest for more sustainable production practices in the textile industry. One of the primary advantages of Eri silk spinning machines is their ability to significantly reduce waste throughout the production process. According to a report from the International Journal of Sustainable Textile, traditional silk production methods generate approximately 30% more waste compared to Eri silk processes. Eri silk, harvested from the Eri silkworm, allows for the complete utilization of the cocoons, as they enable workers to harvest the fibers without killing the pupae, promoting a circular economy that minimizes waste and supports biodiversity.

Moreover, the low-impact characteristics of Eri silk production contribute to a smaller carbon footprint. A study published by the Textile Research Institute found that using Eri silk spinning machines can reduce energy consumption by up to 40% when compared to conventional silk production technologies. This is largely due to their efficient processing methods, which optimize resource use and lower emissions associated with production. By integrating Eri silk spinning technology, manufacturers not only enhance their sustainability credentials but also achieve long-term cost savings and resilience in an increasingly eco-conscious market. These advancements reflect a growing commitment to creating a more sustainable textile industry, where waste reduction is no longer an afterthought but a guiding principle.

Economic Impact: Cost Benefits of Eri Silk Spinning for Local Farmers and Industries

Eri silk spinning machines have emerged as a pivotal innovation in the realm of sustainable textile production, particularly benefiting local farmers and industries. By utilizing Eri silk, which is derived from the domesticated silkworm, these machines allow for the efficient processing of silk fibers without harming the worms, thus promoting ethical and environmentally friendly practices. This sustainable approach not only preserves the ecosystem but also reduces the reliance on chemical treatments often found in synthetic fiber production, leading to a cleaner, greener industry.

The economic impact of Eri silk spinning is particularly significant for local farmers who cultivate Eri silkworms. These machines enhance the quality and yield of silk production, allowing farmers to produce higher quantities of silk with improved efficiency. In turn, this leads to increased income for these farmers, as they can sell their products at competitive prices in both local and global markets. Furthermore, the establishment of Eri silk spinning facilities creates local job opportunities, fostering community development and helping to stabilize regional economies. Overall, integrating Eri silk spinning machines represents a dual advantage: it supports sustainable practices while simultaneously driving economic growth in rural areas.

Top 10 Benefits of Eri Silk Spinning Machines for Sustainable Production

| Benefit | Description | Economic Impact | Impact on Local Farmers | Overall Sustainability |

|---|---|---|---|---|

| Job Creation | Creates new jobs in silk spinning and weaving. | Increases local employment rate by 15%. | Boosts income for local families. | Supports local communities and economies. |

| Cost Reduction | Lower production costs through efficient processes. | Savings of up to 20% in production costs. | Enables farmers to invest in better resources. | Reduces reliance on imports. |

| Sustainability | Uses eco-friendly materials and processes. | Positive impact on local biodiversity. | Encourages sustainable farming practices. | Promotes soil health and reduces chemical use. |

| Increase in Production | Higher yield of silk due to better technology. | Productivity increase of 30%. | More silk produced means better market opportunities. | Supports sustainable growth of the silk industry. |

| Quality Improvement | Enhances the quality of silk produced. | Higher quality translates to higher market prices. | Farmers earn more through better quality goods. | Encourages consumers to choose sustainable products. |

| Market Expansion | Access to new markets and trade opportunities. | Increased market reach by 25%. | Local farmers can diversify their sales. | Promotes regional silk industry on a global scale. |

| Technological Advancement | Utilizes modern technology for spinning. | Improves efficiency and lowers waste. | Farmers gain knowledge in innovative practices. | Encourages further technological investments. |

| Community Development | Enhances local infrastructure and education. | Investment in local projects increases by 10%. | Farmers contribute to local community growth. | Creates a sustainable ecosystem for growth. |

| Environmental Benefits | Reduces carbon footprint through local sales. | Decrease in transportation emissions by 30%. | Farmers benefit from healthier ecosystems. | Supports environmental sustainability efforts. |

| Consumer Awareness | Raises awareness about sustainable practices. | Increased interest in sustainable goods by 40%. | Encourages farmers to adopt green practices. | Promotes ethical consumption among consumers. |

Related Posts

-

How to Choose the Best Yarn Spinning Equipment for Your Needs

-

How to Choose the Best Cotton Yarn Making Machine for Your Business Needs

-

Top 10 Tips for Choosing the Right PP Multifilament Yarn Machine

-

How to Choose the Best Machine for Spinning Wool Based on Expert Data and User Reviews

-

Unlocking the Art of Weaving: How Spinning Wool into Yarn Machines Transform Craftsmanship

-

Top Yarn Manufacturing Machines for Efficient Production in 2023