What is an Industrial Wool Spinning Machine and How Does It Work

The industrial wool spinning machine plays a crucial role in the textile industry, serving as a cornerstone for the production of high-quality wool yarns. These machines are engineered to spin raw wool fibers into yarn, which can then be used for a variety of applications including clothing, upholstery, and industrial products. Understanding how an industrial wool spinning machine operates not only sheds light on the intricate processes behind textile manufacturing but also highlights the technological advancements that make large-scale production possible.

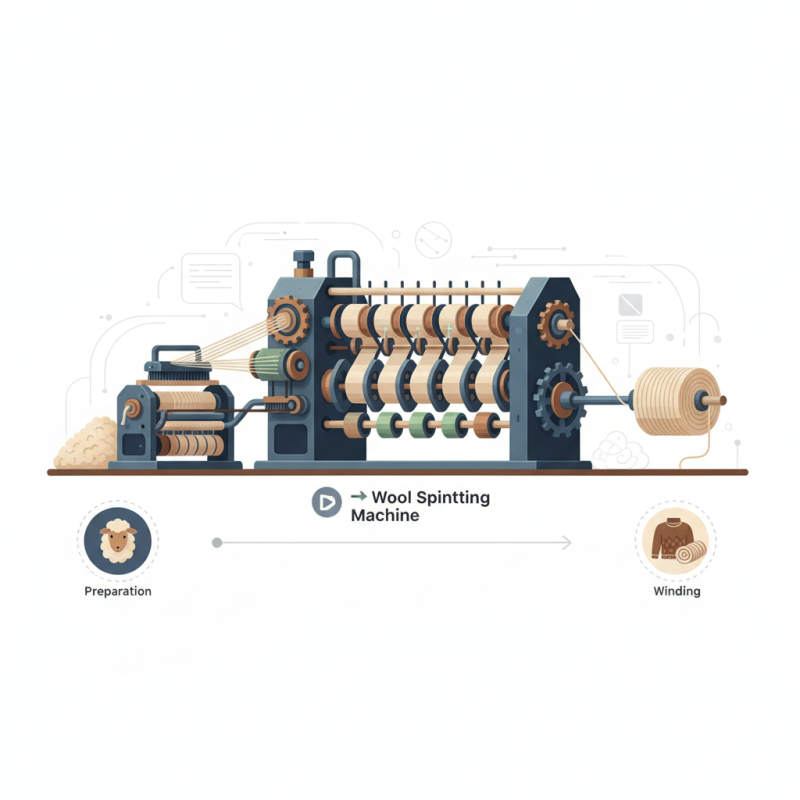

As we delve into the workings of the industrial wool spinning machine, we will explore its various components and how they interact to transform raw materials into finished products. The process begins with the careful preparation of wool fibers, which are then fed into the machine. Through a series of mechanical actions, these fibers are drawn out, twisted, and wound into a cohesive yarn. This seamless integration of technology and craftsmanship underscores the importance of the industrial wool spinning machine in meeting the ever-growing demand for wool products in today’s market.

In summary, the industrial wool spinning machine not only enhances efficiency in wool processing but also upholds the quality standards expected by consumers. By examining the mechanisms and processes involved, we can appreciate the artistry of wool spinning and its significance in the broader context of textile production.

What is an Industrial Wool Spinning Machine?

An industrial wool spinning machine is a specialized device designed for the mass production of wool yarn from raw wool fibers. This machine plays a crucial role in the textile industry, where the demand for quality wool products remains high. According to a recent industry report, the global wool market is projected to reach approximately $18 billion by 2025, largely driven by increasing demand for sustainable and natural fiber products. The industrial wool spinning machine is engineered to optimize the spinning process, ensuring high efficiency and consistency in the final product.

The operation of an industrial wool spinning machine involves several key stages, including carding, drafting, and twisting. Initially, raw wool fibers are carded, which untangles and aligns them into a continuous web. This web is then drafted, meaning it is drawn out to the desired thickness. Finally, the spun fibers are twisted to form strands of yarn. The precision and speed of these machines are impressive; modern spinning machines can produce up to 50 kilograms of yarn per hour, significantly enhancing productivity. Advanced technology in these machines, such as automation and real-time monitoring systems, minimizes human error and optimizes waste reduction, crucial for sustainability in the textile manufacturing process.

What is an Industrial Wool Spinning Machine and How Does It Work

| Feature | Description | Functionality | Benefits |

|---|---|---|---|

| Material Type | Wool fibers, either raw or processed | Transforms wool into yarn | High-quality yarn production |

| Components | Spinning frame, bobbins, spindles | Mechanical operation for spinning | Efficiency and automation |

| Spinning Process | Drafting, twisting, winding | Steps to create uniform yarn | Consistent quality control |

| Production Speed | Fast, capable of handling large batches | Increased throughput | Cost-effective manufacturing |

| Applications | Textiles, knitwear, carpets | Versatile use in fabric production | Broad market reach |

Key Components of Industrial Wool Spinning Machines

Industrial wool spinning machines are essential tools in the textile industry, designed to transform raw wool into usable yarn. These machines comprise several key components that work together to facilitate the spinning process. One of the primary components is the feed system, which regulates the flow of raw wool into the spinning area. This system ensures a consistent supply of fiber that is necessary for producing high-quality yarn.

Another critical component is the spindle, which is responsible for the spinning action. The spindles rotate at high speeds, twisting the fibers together to form a yarn. The tensioning device plays a vital role here as well, maintaining appropriate tension on the fibers during the spinning process, which is crucial for achieving uniformity in the finished product. Additionally, the drafting system helps to stretch and align the fibers before spinning, contributing to the final yarn's strength and texture. Together, these components allow industrial wool spinning machines to efficiently produce high-quality yarn that meets the demands of various textile applications.

Step-by-Step Process of Wool Spinning in Industry

The process of wool spinning in the industry is a meticulous operation that transforms raw wool into usable yarn. It begins with the shearing of sheep, collecting the fleece and preparing it for processing. The raw wool is typically dirty and contains grease, so the next step involves washing it in a series of hot water and detergent baths. This not only cleans but also helps to separate fibers for easier processing.

After washing, the wool is carded, a crucial step where the fibers are disentangled and aligned. This is achieved using carding machines that comb the wool into a sliver, a long, continuous ribbon of fiber. The sliver is then drawn into finer strands through a process called drawing, which further aligns the fibers and prepares them for spinning. Following this, the wool goes through the spinning phase, where it is twisted to form yarn. This involves passing the wool through a spinning machine, creating tension as it is spun, which ultimately determines the thickness and strength of the yarn.

Tips: When working with wool, always ensure that the fleece is free of contaminants, and consider using natural detergents to maintain the integrity of the fibers. Regular maintenance of machinery can also prevent frequent breakdowns and improve production quality. Lastly, properly storing spun yarn in a climate-controlled environment will help preserve its quality and elasticity for future use.

Technological Innovations in Wool Spinning Machinery

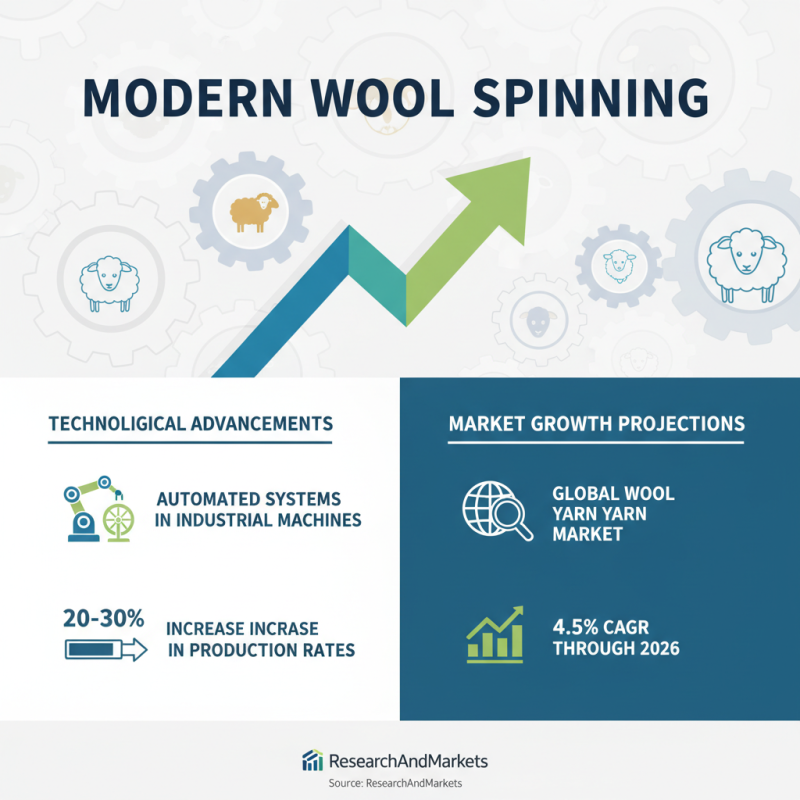

The wool spinning industry has undergone significant advancements in recent years, driven by technological innovations that enhance efficiency and product quality. A key development is the introduction of automated systems in industrial wool spinning machines, which has resulted in a 20-30% increase in production rates. According to a recent market report by ResearchAndMarkets, the global wool yarn market is projected to grow at a CAGR of 4.5% through 2026, underscoring the demand for more efficient spinning technologies.

Moreover, the integration of digital technologies, such as IoT sensors and AI-driven analytics, allows manufacturers to monitor machines in real-time, optimizing performance and reducing downtime. Reports indicate that businesses utilizing smart machinery have experienced a reduction in operational costs by up to 15%, attributing this efficiency to predictive maintenance capabilities and automated fault detection systems. These innovations not only streamline the spinning process but also enable higher consistency in yarn quality, addressing the growing consumer demand for reliable textile products.

In addition to automation and digitalization, sustainable practices in wool spinning technology are also gaining traction. Advanced filtering systems and energy-efficient designs are being implemented to minimize environmental impact. The WWF projects that improving energy efficiency in textile manufacturing can reduce carbon emissions by as much as 30% in the upcoming years, making technological advancements in wool spinning essential not just for economic viability but also for sustainable development in the industry.

Market Trends and Demand for Industrial Wool Products

The demand for industrial wool products has been steadily increasing due to a growing awareness of sustainability and the versatility of wool fibers. As more industries seek eco-friendly materials, the appeal of wool, known for its durability and natural insulating properties, has significantly risen. This trend is particularly evident in sectors such as fashion, textiles, and automotive, where natural fibers are preferred over synthetic options. The shift towards sustainable manufacturing practices is leading to innovative uses of industrial wool, further driving market growth.

To adapt to these trends, manufacturers are investing in advanced industrial wool spinning machines that enhance production efficiency while maintaining the quality of the wool. These machines are designed to meet the rising demand for high-quality wool yarn, enabling the creation of a wider range of products. As the market evolves, companies should also focus on understanding customer preferences and incorporating eco-friendly practices into their production processes.

**Tips:** When considering the purchase of wool products, look for certifications that indicate sustainable sourcing and production methods. Additionally, keep an eye on emerging trends, such as the integration of technology in wool processing, which can offer more sustainable and efficient options in the long run. This approach not only aligns with environmental values but also meets the modern consumer's expectations for quality and responsibility.

Market Trends in Industrial Wool Products

Related Posts

-

What is a Coir Spinning Machine and How Does It Work for Sustainable Products

-

10 Best Spinning Machines for Yarns to Increase Production Efficiency by 30 Percent

-

What is Open End Spinning? Understanding Its Benefits and Applications in Textile Industry

-

Top 10 Spinning Machines for Yarn: An Ultimate Guide for Efficient Production

-

Why You Should Choose a Home Wool Spinning Machine for Your Crafting Needs

-

Unlocking the Art of Weaving: How Spinning Wool into Yarn Machines Transform Craftsmanship