What is a PP Multifilament Yarn Machine and How Does it Work?

The pp multifilament yarn machine plays a crucial role in the textile industry. It produces durable and versatile yarns used in various applications. Understanding how this machine operates offers insights into its efficiency and functionality.

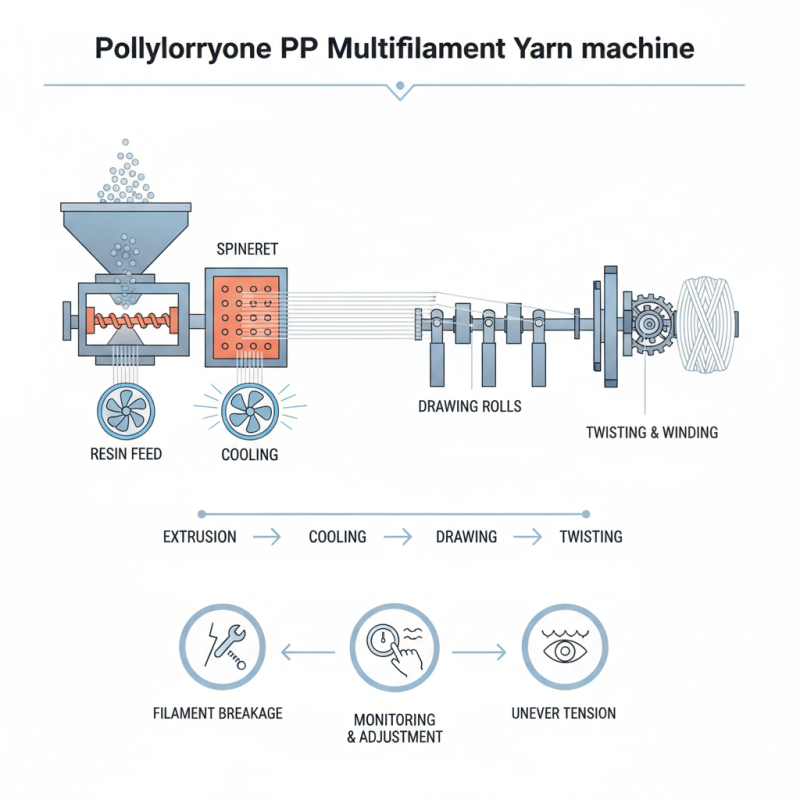

This machine works by extruding polypropylene resin through spinnerets. The extruded filaments are then cooled, drawn, and twisted to create multifilament yarn. Such processes require precision and control. Any flaws can affect quality.

The importance of the pp multifilament yarn machine cannot be overstated. However, challenges arise during production. Issues like filament breakage or uneven tension can occur. Addressing these imperfections requires constant monitoring and adjustments. This reflection on a critical machine in manufacturing highlights both its capabilities and potential pitfalls.

What is PP Multifilament Yarn?

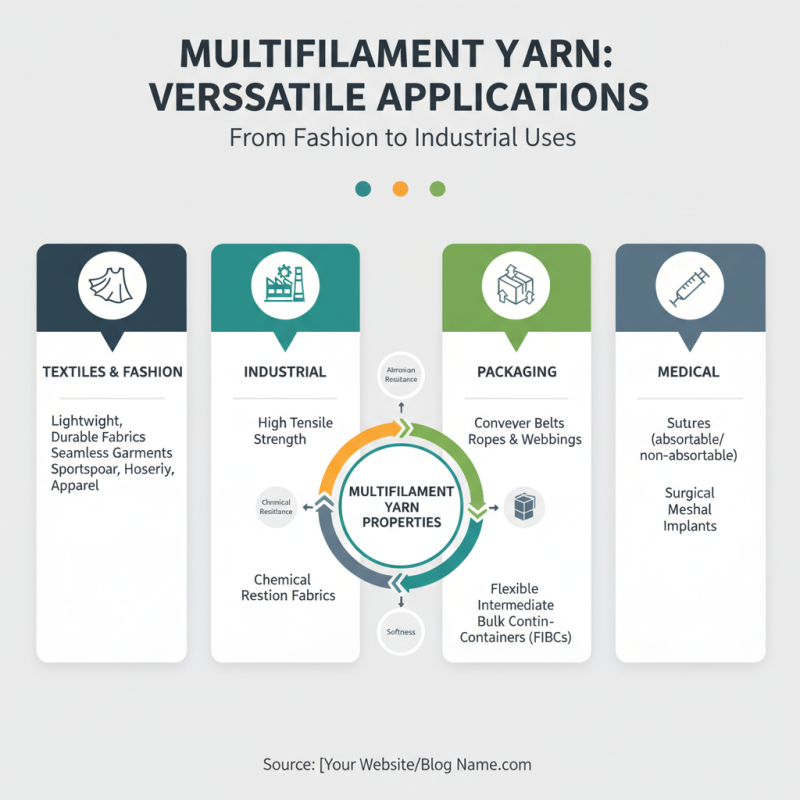

PP multifilament yarn is a type of synthetic fiber made from polypropylene. This fiber is widely used in various applications, including textiles and industrial products. It is known for its lightweight, durability, and resistance to moisture. According to a 2022 industry report, the demand for PP multifilament yarn has steadily grown, especially in the outdoor and sporting goods sectors.

The production process involves melting polypropylene pellets and extruding them through a spinneret. This forms continuous filaments that are then drawn and twisted into yarn. The final product can be treated for additional properties like UV resistance. Data indicates that the global market for polypropylene yarn reached approximately $2 billion last year, highlighting its importance in manufacturing.

Tips: Always monitor the quality control during production. Inconsistent yarn quality can lead to product failures. It’s crucial to regularly test tensile strength and moisture absorbency. Additionally, consider the environmental impact of polypropylene and explore recycling options.

The industry faces challenges too. The process of producing PP yarn can lead to significant waste. Not all manufacturers have adopted eco-friendly practices. Addressing these shortcomings is vital for sustainable growth in the sector.

The Components of a PP Multifilament Yarn Machine

A PP multifilament yarn machine is essential in producing synthetic fibers. It comprises several key components that work collaboratively. These include a feeding device, extrusion unit, cooling system, and winding machinery. Each part plays a vital role in the overall function of the machine.

The feeding device ensures a steady supply of polypropylene pellets. It often includes a hopper that releases materials at a controlled rate. The extrusion unit melts the pellets and forms them into continuous filaments. The process requires precise temperature control to achieve optimal viscosity for smooth production.

Tip: Regular maintenance of the extrusion unit can prevent operational disruptions. A cooling system then solidifies the filaments, often involving air or water. This step is critical; improper cooling can lead to defects in yarn quality.

The winding machinery collects the cooled yarn and organizes it into spools. This part may seem simple, but it’s crucial for handling and storage. Ensuring proper tension during winding is vital to avoid knots and tangles.

Tip: Monitor the yarn tension during production to maintain consistency. Operators sometimes overlook this. This oversight can lead to quality issues, impacting the final product.

The Working Process of a PP Multifilament Yarn Machine

A PP multifilament yarn machine plays a crucial role in textile production. The machine creates polypropylene yarn by spinning multiple filaments together. This process begins with the polymer’s melting and extruding through spinnerets. Each filament is drawn and cooled, ensuring uniform thickness and strength.

In the working process, a series of rollers and tension devices maintain the yarn's quality. Data suggests that these machines can produce up to 1,000 kg of yarn daily. However, not all operations achieve this efficiency, often due to technical difficulties. For example, filament breakage can lead to downtime and lower productivity.

Quality control is pivotal. Operators regularly monitor parameters like temperature and tension. Even minor fluctuations can affect the yarn’s properties. Industry reports indicate that proper calibration can enhance output by nearly 15%. Nonetheless, many manufacturers struggle with maintaining these standards. Thus, continuous improvement and training are necessary for optimizing the yarn production process.

Applications of PP Multifilament Yarn in Various Industries

PP multifilament yarn is used in many industries today. Its versatility makes it ideal for various applications. From textiles to packaging, the uses are numerous. In the fashion industry, this yarn is favored for its lightweight and durable qualities. Designers appreciate its ability to create seamless garments.

In agriculture, PP multifilament yarn is found in erosion control fabrics. These materials help prevent soil loss and promote healthy growth. It's fascinating how a single type of yarn can be crucial for farming. Furthermore, in the fishing industry, fishing nets made from this yarn are strong yet flexible. They endure harsh water conditions.

However, challenges exist with PP multifilament yarn. Recycling these products is difficult. They often end up in landfills instead of being reused. This raises questions about sustainability. The industry must address this issue. Exploring biodegradable alternatives might be necessary. Balancing performance and environmental impact is essential for the future.

Maintenance and Troubleshooting of PP Multifilament Yarn Machines

Maintaining a PP multifilament yarn machine is crucial for optimal performance. Regular checks ensure the machine runs smoothly. Routine maintenance includes inspecting belts, bearings, and gears. According to the International Textile Manufacturers Federation, proper maintenance can extend equipment lifespan by up to 30%. Yet, many operators overlook simple tasks like lubrication.

Troubleshooting is equally important. Common issues include thread breakage and inconsistent tension. Operators should monitor for any unusual sounds or vibrations. These may indicate underlying mechanical problems. A report from the Textile Machinery Association highlights that improper tension can lead to a 15% increase in defect rates. It's essential to adjust settings carefully to prevent this.

Operators should document all maintenance activities. This practice helps in identifying recurring problems. Sometimes, the fixes seem too simple, leading to overlooked small adjustments. However, neglecting these details can lead to larger issues down the line. Regular audits of operational processes can reveal hidden inefficiencies and are necessary for long-term productivity.

What is a PP Multifilament Yarn Machine and How Does it Work? - Maintenance and Troubleshooting of PP Multifilament Yarn Machines

| Feature | Description | Maintenance Tips | Common Issues |

|---|---|---|---|

| Production Capacity | Can produce up to 600 kg of yarn per day. | Regularly check for wear and tear in components. | Yarn breakage or uneven thickness. |

| Material Type | Polypropylene (PP) and other synthetic fibers. | Clean the machine to prevent contamination of materials. | Material jamming in feed system. |

| Power Supply | Typically operates on 380V three-phase power. | Ensure regular inspection of electrical connections. | Power fluctuations affecting performance. |

| Temperature Control | Maintains optimal temperatures during processing. | Regularly calibrate temperature sensors. | Inconsistent yarn performance due to temperature issues. |

Related Posts

-

How to Choose the Best Poy Spinning Machine for Your Manufacturing Needs?

-

How to Choose the Best Machine for Spinning Wool Based on Expert Data and User Reviews

-

Why You Should Invest in an FDY Yarn Machine for Your Textile Business Growth

-

Top 10 Wool Spinning Machines You Need to Know for Your Crafting Projects

-

Top 10 Benefits of Eri Silk Spinning Machines for Sustainable Production

-

Why You Should Choose a Home Wool Spinning Machine for Your Crafting Needs