Top 10 Tips for Choosing the Right PP Multifilament Yarn Machine

In the fast-evolving world of textile manufacturing, selecting the right PP multifilament yarn machine is crucial for optimizing production efficiency and product quality. According to Dr. Emily Smith, a renowned expert in the field of textile engineering, "The choice of a PP multifilament yarn machine can significantly influence not only the yarn characteristics but also the overall sustainability of the production process." As demand for high-quality synthetic textiles escalates, understanding the key factors in choosing the ideal machinery becomes paramount.

Choosing the right PP multifilament yarn machine involves evaluating various aspects such as technology, production capacity, and operational efficiency. With advancements in technology, manufacturers now have access to machines equipped with smart features that enhance monitoring and control capabilities. Additionally, considerations like maintenance ease and energy consumption can lead to long-term benefits both financially and environmentally. With insights from industry leaders, this article aims to guide potential buyers through the critical elements that influence their decision-making process and ensure they invest in machinery that aligns with their production goals and quality standards.

Benefits of Using PP Multifilament Yarn Machines

PP multifilament yarn machines offer numerous advantages that cater to the diverse needs of the textile industry. One of the primary benefits is their ability to produce high-strength and durable yarns, which are essential for various applications such as fishing nets, industrial textiles, and ropes. The versatility of polypropylene fibers allows manufacturers to create textiles that are not only resilient but also lightweight, making them ideal for portable and everyday uses. This capability significantly enhances the overall quality of the end products, ensuring higher customer satisfaction and market competitiveness.

Additionally, the efficiency of PP multifilament yarn machines contributes to increased productivity and cost-effectiveness. These machines are designed for continuous operation, reducing downtime and maximizing output. Furthermore, the energy-efficient design of modern PP multifilament machinery lowers production costs by minimizing power consumption. As a result, businesses can allocate resources more effectively, leading to improved profit margins. The ease of maintenance and automation features also ensures that operators can manage production processes with minimal labor, driving further efficiencies and fostering sustainable manufacturing practices.

Key Features to Consider in PP Multifilament Yarn Machines

When selecting the right PP multifilament yarn machine, several key features should be carefully evaluated to ensure optimal performance and efficiency. First and foremost, the machine’s production capacity is crucial. It should align with your business's scale and output requirements, allowing for flexibility in handling different project sizes. Additionally, the machine's speed and stability during the yarn production process significantly impact the overall quality of the filament. Look for models that provide adjustable speed settings to accommodate various yarn types and processes.

Another critical aspect to consider is the machine’s technology and user interface. Advanced features such as automated tension control, monitoring systems, and user-friendly controls can enhance operational efficiency and reduce the likelihood of errors. Furthermore, the machine's maintenance requirements should not be overlooked; choose a unit designed for ease of maintenance, which can minimize downtime and prolong the life of the equipment. Lastly, evaluate the machine’s energy efficiency, as a more efficient model can lead to significant cost savings over time while also reducing the environmental impact of your manufacturing processes.

Comparison of Different Types of PP Multifilament Yarn Machines

When selecting the right PP multifilament yarn machine, it's essential to understand the various types available in the market. Generally, these machines can be categorized into two main types: conventional multifilament extrusion machines and high-speed multifilament extrusion systems. Conventional machines have been the industry standard for years, typically operating at speeds of around 200-300 meters per minute. However, advancements in technology have led to the rise of high-speed systems, which can achieve speeds exceeding 600 meters per minute. This increase in efficiency can significantly enhance production rates, making it a crucial factor for manufacturers aiming to maximize output.

In terms of performance, the choice between these machine types can impact yarn quality and operational costs. According to a report by the Global Textile Machinery Market, high-speed machines are proven to provide finer denier yarns with improved tensile strength, which is vital for applications in industries such as outdoor fabrics and sports equipment. Furthermore, many modern machines feature superior thermoregulation systems that maintain consistent temperature levels during the extrusion process, reducing energy consumption by up to 20%. By carefully comparing these technologies and their benefits, manufacturers can make informed decisions that align with their production goals and sustainability efforts.

Top 10 Tips for Choosing the Right PP Multifilament Yarn Machine

This chart shows the importance ratings of various factors to consider when choosing a PP multifilament yarn machine. Each factor has been rated on a scale from 1 to 10, indicating its significance in the selection process.

Maintenance Tips for Longevity of PP Multifilament Yarn Machines

Maintaining PP multifilament yarn machines is crucial for ensuring their longevity and optimal performance. Regular maintenance routines, such as cleaning and lubrication, play an essential role in preventing wear and tear. Operators should establish a consistent schedule for checking the machine's components, including bearings, gears, and threading systems, to ensure they are functioning smoothly and to catch any potential issues before they escalate. Using the right lubricants and cleaning agents will help maintain the integrity of the machine and enhance its efficiency.

Additionally, monitoring the operating conditions of the machine can significantly extend its lifespan. This includes regulating the temperature and humidity levels in the workshop environment, as excessive heat or moisture can lead to material degradation and machine malfunction. Furthermore, training staff to handle the machines properly is vital. Proper handling reduces the likelihood of accidents and equipment damage, ensuring that the machinery operates within optimal parameters. Adopting these maintenance tips will not only improve the performance of PP multifilament yarn machines but also contribute to a smoother production process.

Top 10 Tips for Choosing the Right PP Multifilament Yarn Machine - Maintenance Tips for Longevity of PP Multifilament Yarn Machines

| Tip No. | Tip | Description | Maintenance Frequency |

|---|---|---|---|

| 1 | Choose the Right Capacity | Select a machine that can handle your production volume needs. | Monthly |

| 2 | Check for Energy Efficiency | Opt for machines that have energy-saving features. | Quarterly |

| 3 | Evaluate Technology | Consider machines with advanced technology for better output. | Semi-annually |

| 4 | Assess Spare Parts Availability | Ensure spare parts are easily obtainable for repairs. | Annually |

| 5 | Look for User-Friendly Interface | Choose machines that are easy to operate and understand. | Monthly |

| 6 | Inspect Durability | Select machines made from strong materials for longevity. | Annually |

| 7 | Prioritize Safety Features | Ensure the machine has safety implements for operators. | Monthly |

| 8 | Check Manufacturer Support | Opt for machines from manufacturers that offer robust customer support. | As required |

| 9 | Review Client Feedback | Research reviews from other users regarding performance. | Before purchase |

| 10 | Consider Future Needs | Select a machine that can adapt to future production demands. | Ongoing |

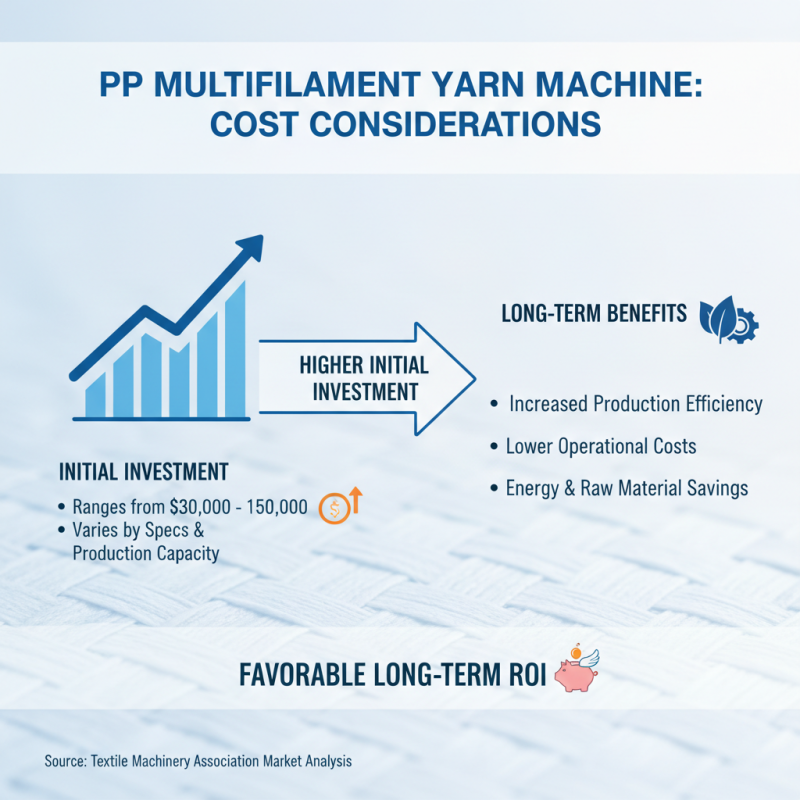

Cost Considerations in Choosing Your PP Multifilament Yarn Machine

When selecting the right PP multifilament yarn machine, cost considerations play a pivotal role in the decision-making process. The initial investment for these machines can range significantly, typically between $30,000 to $150,000, depending on the specifications and production capacity. A detailed market analysis from the Textile Machinery Association indicates that a higher initial investment often correlates to increased production efficiency and lower operational costs over time. Investing in a more advanced machine may lead to savings in energy consumption and raw material waste, creating a favorable long-term return on investment.

Moreover, operational costs must not be overlooked. According to industry reports, the average operational cost for running PP multifilament yarn machines can account for up to 60% of the total expenditure in yarn production. Factors such as maintenance, energy consumption, and labor costs contribute significantly to these expenses. By choosing a machine that offers enhanced automation and reduced manual intervention, companies can mitigate labor costs and improve overall productivity. Additionally, understanding the total cost of ownership—factoring in maintenance, spare parts, and operational efficiency—will ultimately influence the machine's affordability and sustainability in the long run. Additionally, financing options and market trends regarding machinery resale values should also be evaluated to ensure a fully informed purchasing decision.

Related Posts

-

What is Open End Spinning? Understanding Its Benefits and Applications in Textile Industry

-

How to Choose the Best Cotton Yarn Making Machine for Your Business Needs

-

How to Choose the Best FDY Yarn Machine for Optimal Production Efficiency

-

How to Choose the Best Machine for Spinning Wool Based on Expert Data and User Reviews

-

2025 Top 10 Yarn Manufacturing Machines: Boost Efficiency with Advanced Technology

-

How to Choose the Best Yarn Spinning Equipment for Your Needs