What is a Wool Spinning Machine and How Does it Work?

Wool spinning machines are essential in the textile industry. They transform raw wool into yarn. According to the Textile World report, global wool production reached approximately 1 million tons in 2022. This figure highlights the demand for effective spinning technologies.

The wool spinning machine works by carding, drafting, and twisting wool fibers. This process requires precision and efficiency. Some machines can produce up to 150 kg of yarn per hour. However, operators often face challenges in maintaining consistent quality. Variability in wool fibers makes it hard to achieve uniform yarn.

Despite advancements, the industry still encounters issues. Many older machines struggle to meet modern standards. Upgrading can be costly, and not all manufacturers can afford it. The need for training on these machines is critical. Investing in quality equipment and education can enhance output and sustainability in wool spinning.

What is a Wool Spinning Machine? An Overview of Its Functionality

A wool spinning machine is essential in the textile industry. It transforms raw fleece into yarn. This process involves several stages, including carding, spinning, and plying. Carding separates the fibers, creating a fluffy web of wool. Then, it leads to the spinning phase, where machines twist these fibers into strands.

According to industry reports, the global spinning machinery market was valued at approximately $34 billion in 2020. The demand for wool yarn continues to grow, especially for fabrics used in clothing and home textiles. However, the spinning process is not always efficient. Many machines struggle with varying wool grades, resulting in inconsistencies. This can affect the final product's quality, leading to waste and dissatisfaction.

Technological advancements have improved machine performance. Yet, the learning curve remains steep. Operators often need training to manage these machines effectively. With better training, they can minimize errors and improve yield. Even minor adjustments can impact the spinning quality significantly. A small change in tension can lead to issues like yarn breakage or uneven thickness. Addressing these challenges is crucial in maintaining production efficiency and quality.

The History of Wool Spinning Machines and Their Evolution Over Time

The history of wool spinning machines traces back to ancient times. Initially, wool was spun by hand, a labor-intensive process. Early tools included the spindle and the distaff. These primitive methods evolved slowly over centuries.

In the 18th century, the Industrial Revolution changed everything. Inventors created spinning machines to increase production. The spinning jenny, developed in 1764, allowed one worker to spin multiple spools simultaneously. This innovation increased yarn output significantly, setting a new standard in the textile industry.

By the 19th century, advancements continued. The spinning frame appeared, improving consistency and efficiency. Reports show that mechanized spinning reduced costs by over 50%. Yet, these technological shifts had consequences. They displaced skilled workers and raised concerns about quality. Many artisans feared losing their craft to machines. Reflecting on this, we see a balance was needed. The evolution of wool spinning machines reshaped the industry, but at a social cost.

What is a Wool Spinning Machine and How Does it Work? - The History of Wool Spinning Machines and Their Evolution Over Time

| Era | Machine Type | Key Features | Production Rate (kg/hour) | Operational Mechanism |

|---|---|---|---|---|

| 18th Century | Spinning Jenny | Multi-spindle design, manual operation | ~4 | Hand-powered, used for spinning multiple threads simultaneously |

| 19th Century | Water Frame | Water-powered, large-scale production | ~20 | Utilized water energy for spinning large quantities of yarn |

| 20th Century | Ring Spinning Machine | High efficiency, reduced vibration | ~30 | Continuous process with rotating rings for more uniform yarn |

| 21st Century | Open-End Spinning | Increased simplicity, direct spinning from fiber | ~40 | Works by using a rotor to spin yarn more quickly and efficiently |

Key Components of Wool Spinning Machines and Their Roles in Spinning

Wool spinning machines play a crucial role in textile manufacturing. These machines consist of several key components, each serving a specific purpose. The primary component is the feed mechanism, which supplies raw wool into the machine. It must ensure a consistent flow, preventing jams or interruptions during the spinning process.

Another important part is the carding system. This system separates and aligns wool fibers, making them easier to spin. The quality of carding directly affects the final yarn strength. Proper maintenance is essential; worn-out carding elements can lead to uneven yarn thickness. The spinning units follow. They twist the fibers together, converting them into yarn.

Lastly, the tensioning devices maintain the appropriate tension during spinning. If tension is too high or too low, it can cause breakage. This is often overlooked but is crucial for producing high-quality yarn. Each component needs careful calibration. Small errors can result in significant issues down the line. The complexity of these machines highlights the importance of precise engineering and continuous adjustments.

Wool Spinning Machine Productivity by Component

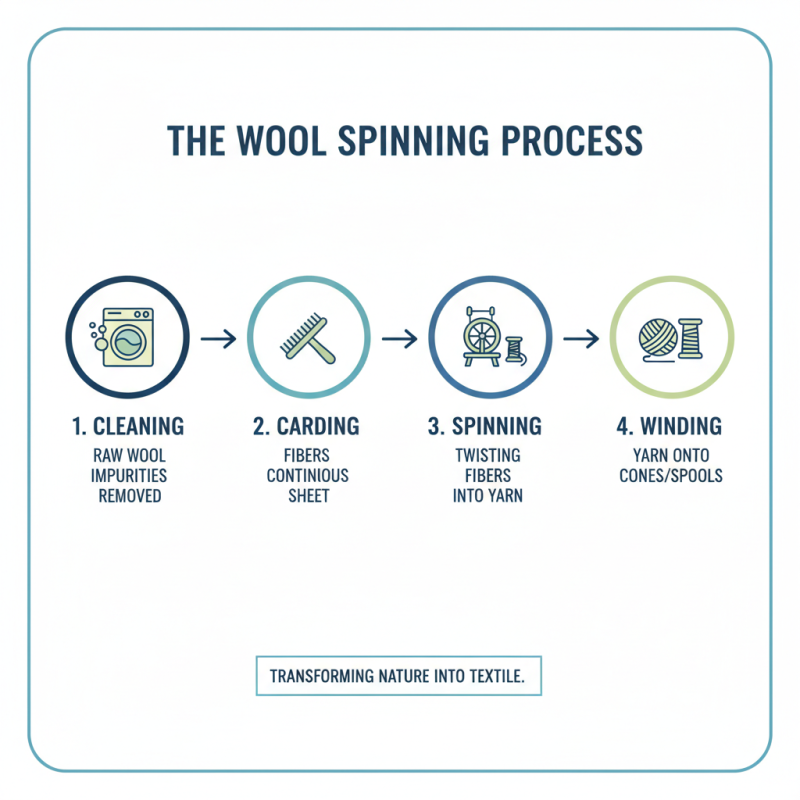

How Wool Spinning Machines Operate: A Step-by-Step Process

Wool spinning machines transform raw wool into usable yarn. Understanding how they operate reveals the intricacies of textile production. The process begins with cleaning the wool, removing impurities. Next, the fibers are carded, aligning them into a continuous sheet.

Once carded, the fibers are drawn out and twisted together. This step creates the yarn’s strength. The machine applies tension to ensure uniform thickness. Sometimes, the wool may tangle or break, causing interruptions. Operators must monitor and make adjustments, reflecting the machine's demands.

Finishing touches involve winding the yarn onto spools. This prepares it for dyeing or knitting. Though efficient, these machines require constant attention. A shift in tension or speed can lead to uneven yarn. Operators often face the challenge of balancing speed and quality. Continuous learning is necessary in this intricate process.

The Impact of Wool Spinning Technology on the Textile Industry Today

Wool spinning technology has transformed the textile industry significantly. In the past, spinning was a labor-intensive process. Today, machines streamline this task, increasing efficiency and quality. These machines help create uniform yarn from raw wool quickly. This process enhances production rates and reduces costs for manufacturers.

As machines evolve, they introduce complexity. Operators need proper training to manage these systems effectively. Without skilled personnel, machinery can lead to waste and inefficiencies. This shift might also lead to fewer traditional craftspeople, raising concerns about preserving artisanal techniques. New technologies sometimes overshadow time-honored practices.

Tips for those in the industry: Always invest in training for your staff. Understanding machinery is essential for optimal performance. Regular maintenance of spinning machines can prevent breakdowns. Also, consider blending traditional craftsmanship with modern technology. This approach might connect the past with the future, ensuring a rich textile heritage. Embrace both innovation and tradition to create a balanced production environment.

Related Posts

-

What is a Machine for Spinning Wool and How Does It Work?

-

How to Choose the Best Machine for Spinning Wool Based on Expert Data and User Reviews

-

Top 10 Wool Spinning Machines You Need to Know for Your Crafting Projects

-

Why You Should Choose an Automatic Wool Spinning Machine for Your Business

-

2026 How to Choose the Best Automatic Wool Spinning Machine for Your Needs

-

Unlocking the Art of Weaving: How Spinning Wool into Yarn Machines Transform Craftsmanship