What is a Yarn Manufacturing Machine and How Does It Work?

The yarn manufacturing machine is a crucial player in the textile industry. According to a recent report by Market Research Future, the global yarn production market was valued at over $200 billion in 2022. With a projected growth rate of 5.2% through 2030, the importance of efficient machinery cannot be overstated. Industry expert Dr. Emily Carter states, "The advancement of yarn manufacturing machines significantly boosts production efficiency while maintaining quality."

This machinery is designed to convert raw fibers into yarn through a series of intricate processes. These processes include carding, spinning, and twisting, which transform fibers into usable threads. However, challenges remain in optimizing production and minimizing waste. Innovations in technology aim to address these issues, yet many manufacturers still struggle with outdated machinery. As production costs rise, the need for more efficient yarn manufacturing machines becomes evident.

In the evolving landscape of textile production, understanding and improving yarn manufacturing processes is vital. The balance between cost, efficiency, and sustainability represents a critical challenge for many companies. As we explore the workings of yarn manufacturing machines, it becomes clear that the future of the textile industry hinges on these essential tools.

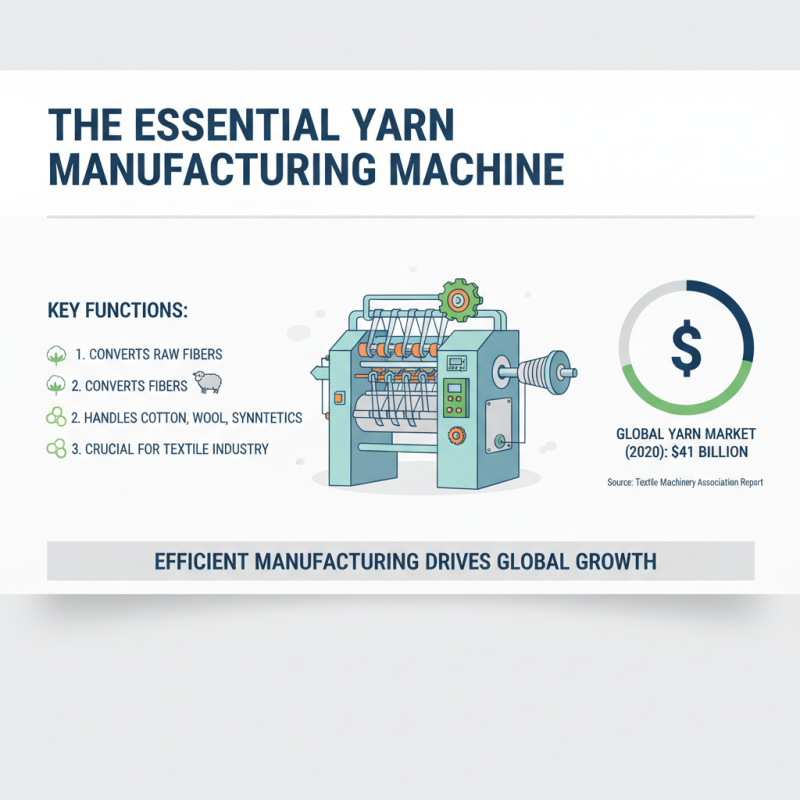

What is a Yarn Manufacturing Machine?

A yarn manufacturing machine is essential in the textile industry. It converts raw fibers into yarns. These machines can handle various fiber types, including cotton, wool, and synthetic materials. According to a report by the Textile Machinery Association, the global yarn market was valued at around $41 billion in 2020. This figure highlights the significance of efficient manufacturing processes.

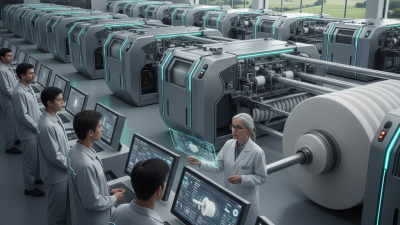

In operation, a yarn manufacturing machine often includes several key components. Spinning frames twist fibers together, creating strong yarn strands. In 2023, reports indicate that automation in spinning processes could reduce labor costs by up to 30%. However, implementing such technology requires careful consideration. Not all facilities can afford the transition to automation.

Despite advancements, challenges persist. The quality of yarn can vary based on machine calibration. An improperly set machine may produce uneven strands. This inconsistency can lead to product waste and dissatisfied customers. Striking a balance between technology and manual oversight remains a topic of discussion in the industry. Innovations continue, but the pursuit of perfection in yarn production is ongoing.

Overview of Yarn Manufacturing Processes and Their Importance

Yarn manufacturing processes are vital in the textile industry. They transform raw fibers into usable yarn. This yarn serves as the foundation for fabric production. Various steps are involved, such as spinning, twisting, and winding. Each step significantly impacts the quality of the final product.

The spinning process is crucial. It determines the thickness and strength of yarn. Different spinning methods can produce various yarn types. For instance, ring spinning is popular for its versatility. However, it can be slow and inefficient compared to other techniques. This trade-off is often a focus of debate among manufacturers.

Winding is another essential step. It prepares yarn for weaving or knitting. During winding, yarn must be carefully managed to avoid tangles. A messy winding process can lead to production delays. Reflecting on these complexities helps improve manufacturing efficiency. Each decision influences the quality and sustainability of the textile supply chain.

Key Components of Yarn Manufacturing Machines and Their Functions

Yarn manufacturing machines play a crucial role in textile production. These machines consist of several key components that work together to transform raw fibers into finished yarn.

The spinning frame is one of the main components. It twists fibers into strands. According to industry reports, modern spinning frames can produce thousands of meters of yarn per hour. Another vital part is the drafting system. It helps to pull fibers into thinner strands, ensuring uniformity. This is essential for quality control in textiles. The bobbin winder, on the other hand, winds the yarn onto spools, ready for further processing.

**Tips:** Regular maintenance is key. Clean the machines often to prevent buildup of dust and fibers. This can help avoid costly breakdowns. Also, ensure that the spinning speed is appropriate for the type of fiber being used. Too fast can lead to inconsistencies.

Monitoring machine performance is crucial. Data tracking can help identify patterns in production. Understand the capabilities and limitations of your machines. Not all systems are designed for every type of fiber. Consider testing different settings for optimal results.

Yarn Manufacturing Machine Components and Functions

| Component | Function | Material Used | Technical Specifications |

|---|---|---|---|

| Spinning Frame | Converts fiber into yarn | Steel, Aluminum | Speed: 800-2000 rpm |

| Roving Frame | Prepares roving for spinning | Steel, Plastic | Drafting Range: 10-30 |

| Winding Machine | Winds the finished yarn onto packages | Steel, Electrical Components | Speed: 200-600 m/min |

| Twisting Machine | Twists multiple strands of yarn | Steel, Electronic Controls | Twist Rate: 100-300 tpm |

| Carding Machine | Cards fiber into a uniform web | Steel, Synthetic Materials | Production: up to 500 kg/h |

The Working Mechanism of Yarn Production: Step-by-Step Process

Yarn manufacturing is an intricate process. It begins with raw fibers, often cotton or wool. The fibers are cleaned and prepared for spinning. This step is crucial for producing quality yarn. Dirt and impurities can weaken the final product.

In the spinning process, fibers are drawn and twisted together. This forms a continuous strand of yarn. The machine works by feeding the fibers into a spinning frame. It applies tension and twist them into a fine yarn. Precision is important at this stage. A slight error can lead to inconsistency in thickness.

Tips for efficient yarn production: Monitor the fiber quality regularly. Keep the machines well-maintained to avoid breakdowns. Pay attention to tension; uneven tension can spoil the yarn's quality.

After spinning, the yarn is wound onto spools. These spools are then ready for dyeing or weaving. Each step has its challenges. Variations in fiber type can affect the production time. Adjustments may be necessary to achieve the desired outcome. Reflect on these processes regularly to enhance efficiency.

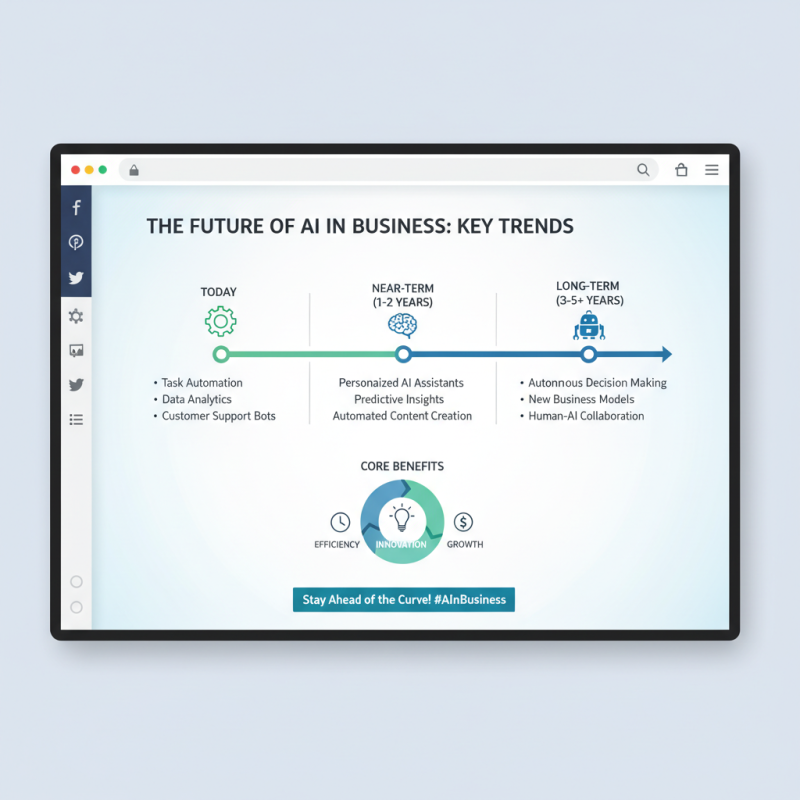

Industry Standards and Innovations in Yarn Manufacturing Technology

Yarn manufacturing technology has evolved significantly. Industry standards now focus on sustainability and efficiency. Innovative machines and techniques are being developed to meet these needs. For instance, energy-efficient motors are being integrated into production lines. This allows companies to reduce their carbon footprint while maintaining high-quality output.

Tips: Always check machine specifications. Some machines consume more energy than advertised. Adjusting operations can lead to savings.

Quality control also plays a crucial role. New technologies enable real-time monitoring of yarn properties. This ensures consistent quality throughout production. However, not all factories have adopted these innovations yet. There is still a gap between technological advancements and practical implementation.

Tips: Invest in employee training. Skilled workers can better utilize modern machines and improve production efficiency.

Moreover, advances in material science are pushing boundaries. Biodegradable fibers and smart textiles are examples. Yet, the adoption of these materials is slow. Companies often hesitate to switch due to cost or uncertainty. Addressing these concerns is essential for progress in yarn manufacturing.

Related Posts

-

2025 Top 10 Yarn Manufacturing Machines: Boost Efficiency with Advanced Technology

-

Top Yarn Manufacturing Machines for Efficient Production in 2023

-

Why You Should Choose a Home Wool Spinning Machine for Your Crafting Needs

-

What is a Coir Spinning Machine and How Does It Work for Sustainable Products

-

10 Best Spinning Machines for Yarns to Increase Production Efficiency by 30 Percent

-

2026 How to Choose the Best Automatic Wool Spinning Machine for Your Needs