Top Yarn Manufacturing Machines for Efficient Production in 2023

In the rapidly evolving textile industry, the efficiency and technology of yarn manufacturing machines play a crucial role in meeting the demands of modern production. As we venture into 2023, manufacturers face the challenge of optimizing their operations to enhance productivity while maintaining quality. Innovations in machine design and functionality have transformed traditional yarn production processes, paving the way for more streamlined, automated methods that reduce waste and improve output.

This article delves into the top yarn manufacturing machines that are reshaping the landscape of textile production this year. By examining the latest advancements in technology, we will explore how these machines not only boost efficiency but also adapt to diverse material requirements and production scales. Understanding the capabilities of these machines is essential for manufacturers aiming to stay competitive in an ever-changing market, especially as consumer demands evolve towards sustainability and customization.

Ultimately, the right yarn manufacturing machine can be a game-changer for businesses looking to enhance their productivity while navigating the complexities of modern textile demands. This exploration of top machines in 2023 aims to provide valuable insights and guidance for industry professionals seeking to leverage technology for improved production outcomes.

Overview of Yarn Manufacturing Machines and Their Importance

In the realm of textile production, yarn manufacturing machines play a pivotal role in ensuring efficient and high-quality output. With the global yarn market projected to reach approximately 31 billion USD by 2026, manufacturers are increasingly investing in advanced machinery that enhances productivity and reduces operational costs. The integration of automation and technology in yarn manufacturing not only allows for faster production rates but also ensures consistency in quality, which is vital in meeting the evolving demands of the industry.

The significance of these machines extends beyond mere production capabilities; they are crucial for sustainability and waste reduction in the manufacturing process. According to a report by the Textile Machinery Association, over 65% of manufacturing waste can be minimized with the proper selection of machinery and technology. Innovations such as digital yarn production systems and automatic spoolers have been shown to cut energy consumption by up to 30%, illustrating the dual benefit of efficiency and environmental responsibility. As the industry progresses into 2023, the continued evolution of yarn manufacturing machines is essential for companies aiming to stay competitive while adhering to sustainability goals.

Key Features of Top Yarn Manufacturing Machines in 2023

In 2023, the yarn manufacturing industry continues to evolve, driven by technological advancements that enhance production efficiency and product quality. Among the key features of top yarn manufacturing machines, automation stands out as a significant trend. According to a report by MarketsandMarkets, the global market for industrial automation is projected to grow from $175 billion in 2021 to $267 billion by 2028. This shift towards automated solutions allows manufacturers to achieve higher output rates while reducing labor costs and human error, ensuring a more reliable production process.

Another critical feature is the integration of IoT (Internet of Things) technologies, enabling real-time monitoring and data analytics. A report by Technavio indicates that the IoT in the textile industry is expected to grow at a CAGR of 20% between 2021 and 2025. By utilizing IoT, yarn manufacturers can track machine performance, predict maintenance needs, and optimize production flow. This not only increases operational efficiency but also contributes to more sustainable practices, as resource management becomes more precise and waste is minimized.

Lastly, advancements in energy efficiency are paramount in the design of modern yarn manufacturing machines. With energy costs contributing significantly to overall operational expenses, manufacturers are increasingly adopting equipment that consumes less energy while maintaining high productivity levels. As per the International Energy Agency, improving energy efficiency in the industrial sector could reduce global energy consumption by up to 30% by 2030. Such innovations are essential not only for improving profit margins but also for meeting global sustainability goals.

Comparison of Leading Yarn Manufacturing Brands and Their Technologies

The yarn manufacturing industry has seen significant advancements in technology, leading to increased efficiency and productivity in production facilities. Key players in the market have developed innovative machinery that improves various stages of the manufacturing process, such as spinning, twisting, and winding. These advancements not only enhance the quality of the yarn produced but also optimize the energy consumption and operational costs associated with production.

When comparing leading yarn manufacturing brands, it’s essential to look into the different technologies they employ. Some manufacturers focus on automation, utilizing smart machines that can be monitored remotely to maximize uptime and reduce labor costs. Others emphasize sustainability by developing machines that minimize waste and use eco-friendly materials. This technological diversity allows manufacturers to choose equipment that best suits their operational needs and aligns with their production goals.

Tips: When selecting yarn manufacturing machinery, consider not only the initial investment but also the long-term operational costs. Look for brands that offer robust after-sales support and training for your team. Additionally, evaluate the adaptability of the machines to future technologies to ensure your production remains competitive as industry standards evolve.

Top Yarn Manufacturing Machines for Efficient Production in 2023

| Machine Type | Production Capacity (kg/h) | Energy Consumption (kW) | Technology Features | Maintenance Frequency (months) |

|---|---|---|---|---|

| Ring Spinning Machine | 400 | 25 | Automatic bobbin change, high-speed production | 6 |

| Open-End Spinning Machine | 500 | 30 | Low yarn breakage, continuous operation | 4 |

| Air-Jet Spinning Machine | 300 | 22 | High-quality yarn, reduced labor cost | 5 |

| Compact Spinning Machine | 350 | 28 | Compact yarn formation, excellent fiber utilization | 6 |

| Drawing Machine | 450 | 20 | Precision control, adjustable speed ratios | 3 |

Sustainability Trends in Yarn Manufacturing Machine Production

The yarn manufacturing industry is experiencing a significant shift toward sustainability in 2023, driven by growing environmental awareness and evolving consumer preferences. Manufacturers are increasingly adopting eco-friendly practices, such as using renewable resources, reducing waste, and incorporating recycled materials into their production processes. This trend not only helps minimize the environmental impact but also appeals to a conscientious consumer base eager to support sustainable brands.

To align with these sustainability trends, companies are investing in advanced yarn manufacturing machines that prioritize energy efficiency and reduce emissions. Innovations such as waterless dyeing technologies and machines that optimize fiber utilization are becoming more common, allowing producers to decrease their carbon footprint substantially. As these technologies advance, they not only make production more efficient but also contribute to a more circular economy within the textile industry.

**Tips for Implementing Sustainable Practices:** When considering yarn manufacturing, evaluate your production process for wasted resources and identify areas for improvement. Switching to energy-efficient machinery can yield long-term cost savings while promoting sustainability. Additionally, explore partnerships with suppliers who prioritize sustainability to enhance your eco-friendly practices further and promote a greener supply chain. Embracing these changes can position your business as a leader in sustainable yarn production.

Top Yarn Manufacturing Machines - Production Efficiency Trends in 2023

Future Innovations in Yarn Manufacturing Equipment and Automation

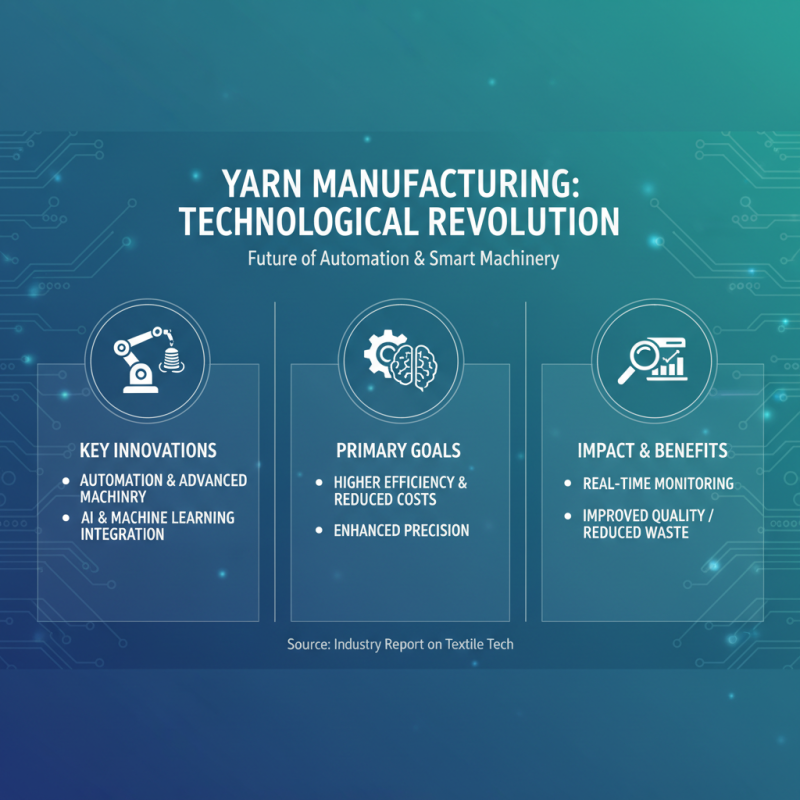

The yarn manufacturing industry is on the brink of a technological revolution, with future innovations focusing heavily on automation and advanced machinery. As manufacturers strive for higher efficiency and reduced production costs, the integration of smart technologies such as artificial intelligence and machine learning is becoming increasingly prevalent. These technologies not only enhance the precision of yarn production but also enable real-time monitoring of manufacturing processes, leading to significant improvements in quality control and reduced waste.

Furthermore, advancements in robotics are paving the way for fully automated yarn manufacturing systems. These systems can streamline operations by performing repetitive tasks, such as winding and packaging, with minimal human intervention. This not only accelerates production cycles but also allows skilled workers to focus on more complex problem-solving tasks, thus enhancing overall productivity. As companies invest in these innovative solutions, the landscape of yarn manufacturing is expected to evolve, making it more agile and responsive to market demands while maintaining a focus on sustainability.

Related Posts

-

2025 Top 10 Yarn Manufacturing Machines: Boost Efficiency with Advanced Technology

-

Why You Should Choose a Home Wool Spinning Machine for Your Crafting Needs

-

How to Choose the Best Yarn Spinning Equipment for Your Needs

-

How to Choose the Best Automatic Yarn Spinning Machine for Your Business

-

How to Choose the Best Cotton Yarn Making Machine for Your Business Needs

-

How to Choose the Best FDY Yarn Machine for Optimal Production Efficiency