Why Choose a Yarn Spinner Machine for Efficient Textile Production Solutions

In the constantly evolving textile industry, manufacturers are always on the lookout for innovative solutions that enhance productivity and improve efficiency. One of the most significant advancements in this field is the introduction of the yarn spinner machine. This remarkable piece of equipment revolutionizes the spinning process, allowing textile producers to create high-quality yarns with greater speed and precision. By adopting a yarn spinner machine, companies can streamline their operations, reduce production costs, and remain competitive in a market that demands both quality and quick turnaround times.

The advantages of using a yarn spinner machine extend beyond mere efficiency; they also encompass the ability to produce a diverse range of yarn types. Whether catering to the fast fashion industry or producing high-end textiles, this machine meets the varying demands of different markets. Furthermore, advancements in technology have led to enhanced automation and user-friendly interfaces, making it easier for operators to achieve optimal results with minimal training. In embracing these cutting-edge solutions, manufacturers position themselves to not only meet current market needs but to also anticipate future trends in textile production.

Benefits of Using Yarn Spinner Machines in Textile Production Efficiency

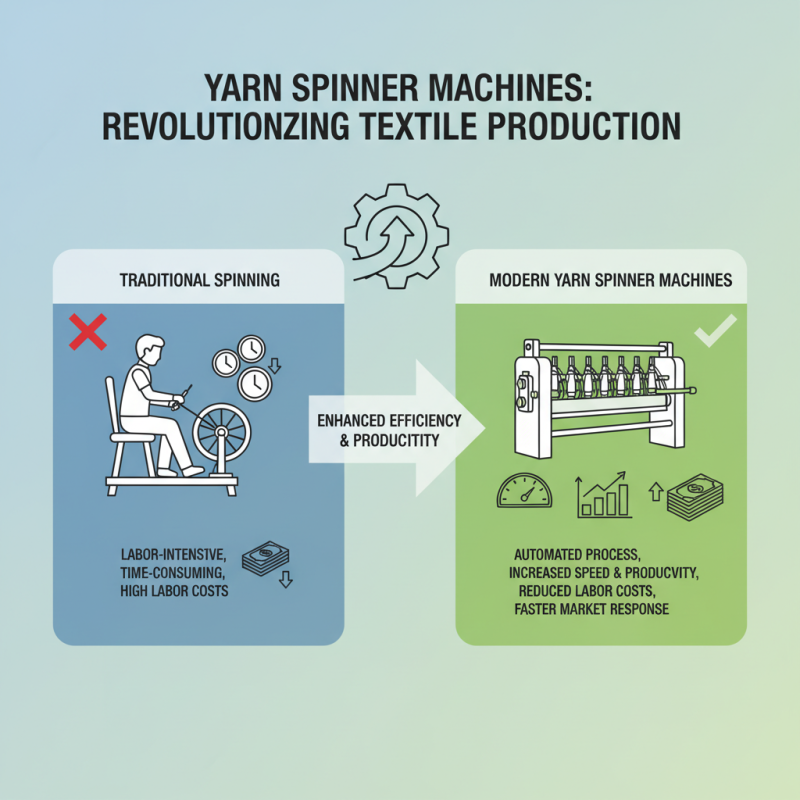

Yarn spinner machines have revolutionized the textile production industry by significantly enhancing efficiency and productivity. One of the primary benefits of these machines is their ability to streamline the spinning process. Traditional spinning methods can be labor-intensive and time-consuming; however, modern yarn spinner machines automate many of these tasks. This increases the speed of production while reducing labor costs, allowing manufacturers to respond more swiftly to market demands.

Moreover, yarn spinner machines improve the consistency and quality of the yarn produced. These machines use advanced technology to maintain uniform tension and precise control over the spinning process, resulting in higher-quality yarns with fewer defects. This enhanced quality not only meets the stringent requirements of modern textile applications but also reduces waste, contributing to a more sustainable production cycle. By investing in yarn spinner machines, textile manufacturers can achieve greater operational efficiency, ultimately leading to higher profitability and competitiveness in a fast-paced industry.

Comparative Analysis: Yarn Spinner Machines vs Traditional Spinning Methods

In the realm of textile production, the choice between yarn spinner machines and traditional spinning methods presents a significant strategic decision for manufacturers. Yarn spinner machines offer advanced automation and precision that traditional methods often lack. These machines utilize cutting-edge technology to produce yarn at a higher speed and with greater consistency, resulting in improved overall efficiency. Unlike manual spinning, which can be labor-intensive and time-consuming, yarn spinner machines streamline the entire process, allowing for faster turnaround times and increased production volumes.

Traditional spinning methods rely heavily on human skill and experience, which can lead to variability in yarn quality and production rates. While these methods have their charm and can produce unique textures, they do not match the scalability and reliability of modern yarn spinner machines. Furthermore, the automation involved in yarn spinning minimizes the margin for error, thus reducing waste and enhancing the sustainability of production operations. This comparative advantage is essential in a market that increasingly values not only quality but also efficiency and cost-effectiveness. Therefore, opting for yarn spinner machines can be a game changer for textile manufacturers aiming to meet modern demands while maintaining high standards in production.

Why Choose a Yarn Spinner Machine for Efficient Textile Production Solutions - Comparative Analysis: Yarn Spinner Machines vs Traditional Spinning Methods

| Criterion | Yarn Spinner Machines | Traditional Spinning Methods |

|---|---|---|

| Production Speed | High (up to 150 kg/hour) | Moderate (30-50 kg/hour) |

| Energy Efficiency | High (20% less energy consumption) | Low (higher energy usage) |

| Labor Dependency | Low (automated processes) | High (manual labor needed) |

| Quality of Yarn | Consistent and high quality | Variable quality |

| Initial Investment Cost | High (Requires upfront capital) | Lower (but higher long-term costs) |

| Maintenance | Lower and predictable | Higher and variable |

Impact of Yarn Spinner Machines on Production Speed and Cost Reduction

The advent of yarn spinner machines has revolutionized the textile production landscape by significantly enhancing production speed and reducing costs. These advanced machines streamline the spinning process, allowing manufacturers to produce yarn at a faster rate compared to traditional methods. By automating various stages of yarn production, companies can achieve higher throughput, meeting increasing demand without compromising on quality. This acceleration in production directly contributes to reduced lead times, enabling manufacturers to respond more rapidly to market trends and customer needs.

Furthermore, the implementation of yarn spinner machines leads to substantial cost savings. Automated spinning processes minimize labor requirements, lowering the overall operational expenses associated with textile production. Additionally, these machines optimize raw material usage, decreasing waste and maximizing efficiency. The combination of faster production speeds and cost reductions positions businesses to enhance their profitability while remaining competitive in a rapidly evolving industry.

The impact of yarn spinner machines is thus profound, transforming production capabilities and setting a new standard for excellence in textile manufacturing.

Technological Advances in Yarn Spinner Machines Enhancing Productivity

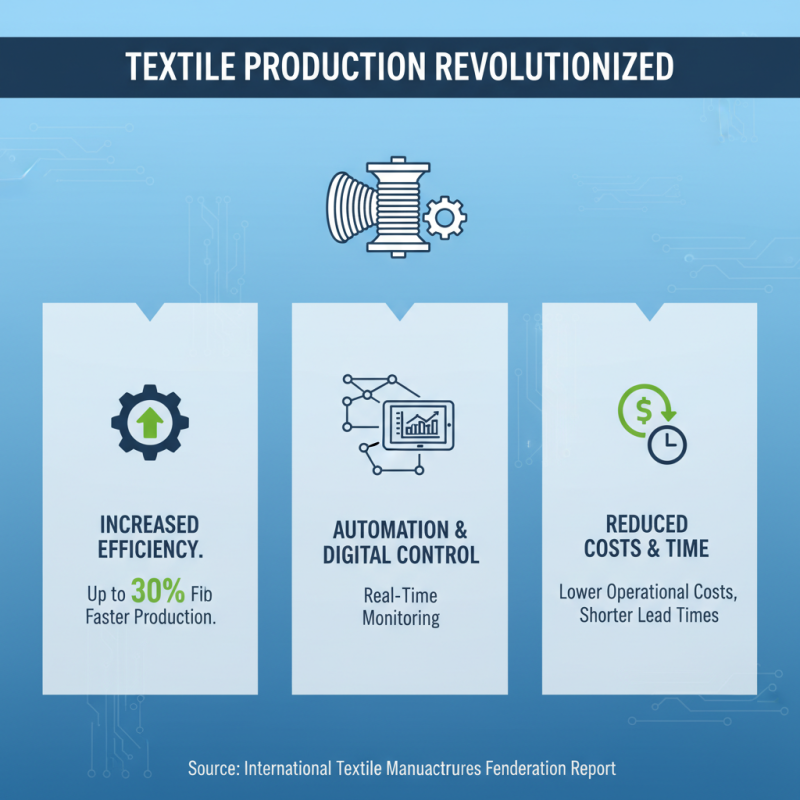

Technological advances in yarn spinner machines have significantly transformed the textile production landscape, optimizing efficiency and productivity in ways that were previously unattainable. Modern yarn spinner machines incorporate state-of-the-art automation and digital control systems, allowing manufacturers to monitor processes in real-time. According to a report by the International Textile Manufacturers Federation, the implementation of advanced machinery can increase production speed by up to 30%, substantially reducing operational costs and lead times.

Additionally, innovations such as the integration of IoT (Internet of Things) technologies enable predictive maintenance and reduce downtime. Data analytics tools embedded in these machines help identify trends in manufacturing processes, leading to more informed decision-making and enhanced resource management. Studies show that companies adopting these technological advancements can expect an increase of up to 20% in overall efficiency, evidencing the importance of investing in modern equipment for any serious textile producer.

Tips: When considering upgrading to a new yarn spinner machine, evaluate the potential ROI by analyzing current production metrics compared to expected outcomes with the new equipment. Regular training sessions on utilizing new technology can also maximize the benefits gained from these advanced machines. Additionally, staying updated on machine maintenance schedules ensures optimal performance and longevity of your investment.

Case Studies: Successful Implementation of Yarn Spinner Machines in Factories

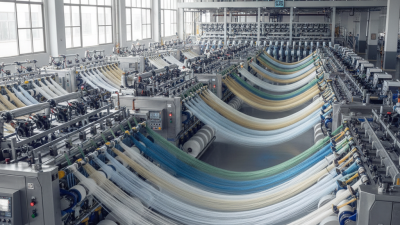

Yarn spinner machines have revolutionized textile production by enhancing efficiency and reducing waste. A prominent example can be seen in a textile factory that implemented this technology, leading to a remarkable increase in output. By optimizing the spinning process, the facility not only streamlined production schedules but also minimized downtime. The case study reveals that the integration of yarn spinner machines reduced labor costs and material usage, ultimately contributing to a leaner production cycle.

Another fascinating instance involves a factory that faced challenges in maintaining consistent yarn quality. After adopting yarn spinner machines, quality control issues were significantly mitigated. The precision of these machines allowed for uniform spinning, which directly improved the overall product quality. As a result, the factory experienced a boost in customer satisfaction and brand reputation. This transformation demonstrates how effective technology can lead to substantial benefits in the competitive textile industry.

Yarn Spinner Machine Efficiency in Textile Production

Related Posts

-

Top 10 Spinning Machines for Yarn: An Ultimate Guide for Efficient Production

-

Unlocking the Art of Weaving: How Spinning Wool into Yarn Machines Transform Craftsmanship

-

Top 10 Best FDY Yarn Machines for High Quality Fabric Production

-

What is a Coir Spinning Machine and How Does It Work for Sustainable Products

-

Why You Should Invest in an FDY Yarn Machine for Your Textile Business Growth

-

10 Best Spinning Machines for Yarns to Increase Production Efficiency by 30 Percent